***Ordering Procedure/Pricing Guideline system generator is within each Model brochure download below.

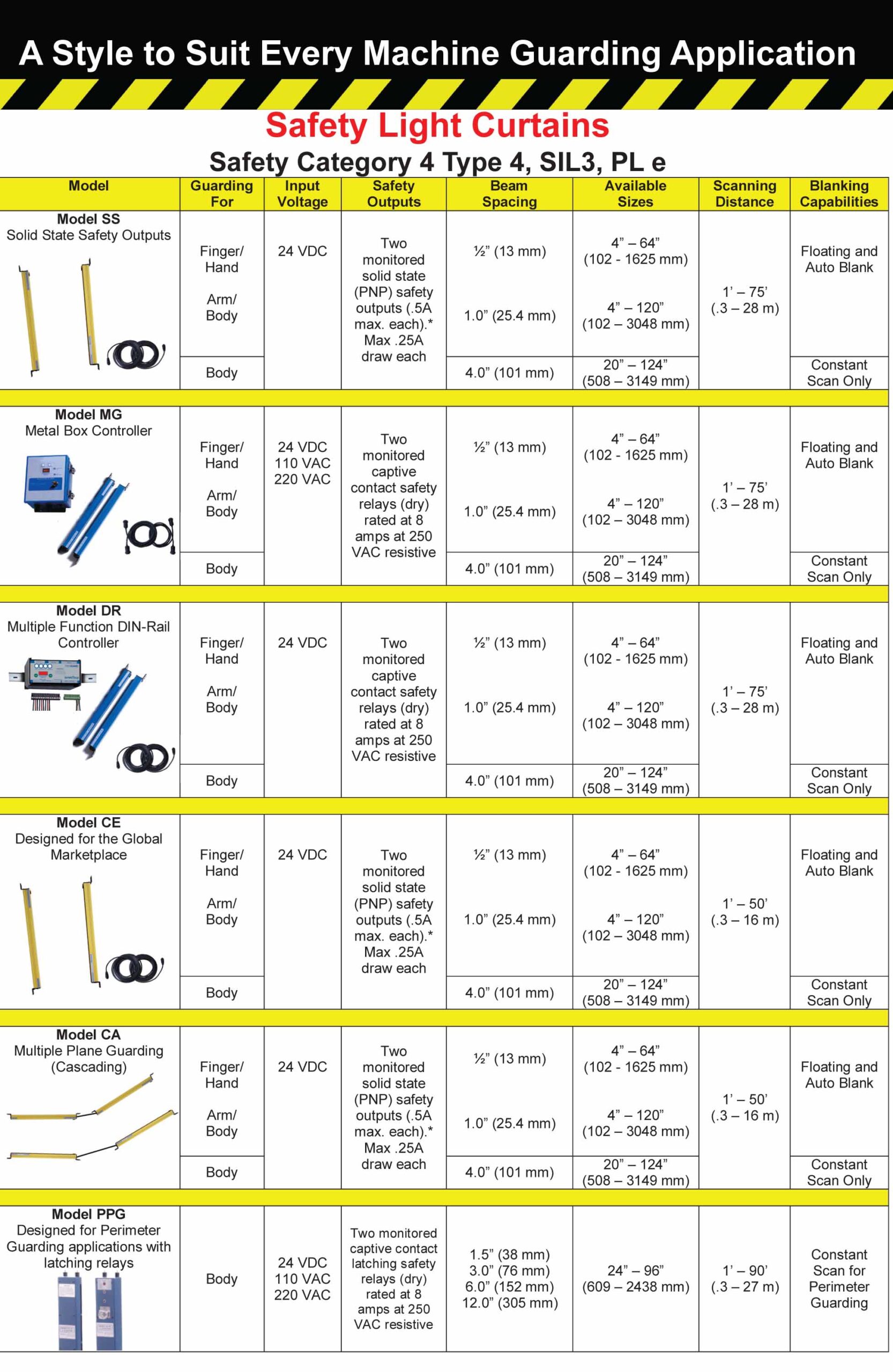

Model SS Safety Light Curtains – Safety light curtain with no 3rd box or controller. Pylons are rated Nema 4 (IP 65) and has two monitored solid state PNP outputs. Mechanical captive contact (dry) safety relays also available. Input power is 24VDC. Complete system diagnostics, mounting brackets and connection cables are supplied standard. Type 4 / Category 4, SIL 3, PL e. Made in USA.

Model SS Safety Light Curtains – Safety light curtain with no 3rd box or controller. Pylons are rated Nema 4 (IP 65) and has two monitored solid state PNP outputs. Mechanical captive contact (dry) safety relays also available. Input power is 24VDC. Complete system diagnostics, mounting brackets and connection cables are supplied standard. Type 4 / Category 4, SIL 3, PL e. Made in USA.

Model MG Safety Light Curtains – A safety light curtain with a free standing Metal Box Smart Controller for light curtains (up to four individual sets of pylons) that features a multi-lingual diagnostic message display and a two year warranty. It’s standard features and capabilities make it a smart choice for your safeguarding needs. Our Model MG safety light curtain meets or exceeds OSHA, ANSI, CSA, RIA and CE Standards. It has a Safety Category 4 rating per IEC 61496, SIL3 per IEC 61508, PL e per EN ISO 13849. The Model MG light curtain also offers total system diagnostics with message display for component and board level assemblies and status updates. Two sets of operator status indicators, modular design for easy in-field maintenance, self-checking circuitry and fault relay output are built-in standard. A lockable controller box (NEMA 12 & 13 (IP 64)), easy access for wiring, push button reset with memory, high immunity to strobe type and weld flash generated light and miniature design make the Model MG Safety Light Curtain easy to interface with all types of machine controllers and PLC’s. Extended scanning ranges are also available up to 75’ (23m). Also offered is a single/multiple floating beam blanking with indicator, single/multiple fixed beam blanking with indicator and auto blanking feature with indicator, built-in machine interface monitoring. Thirty standard light curtain sizes are available from 4” (102mm) to 120” (3048mm) lengths in 4” (102mm) increments. Made in USA..

Model MG Safety Light Curtains – A safety light curtain with a free standing Metal Box Smart Controller for light curtains (up to four individual sets of pylons) that features a multi-lingual diagnostic message display and a two year warranty. It’s standard features and capabilities make it a smart choice for your safeguarding needs. Our Model MG safety light curtain meets or exceeds OSHA, ANSI, CSA, RIA and CE Standards. It has a Safety Category 4 rating per IEC 61496, SIL3 per IEC 61508, PL e per EN ISO 13849. The Model MG light curtain also offers total system diagnostics with message display for component and board level assemblies and status updates. Two sets of operator status indicators, modular design for easy in-field maintenance, self-checking circuitry and fault relay output are built-in standard. A lockable controller box (NEMA 12 & 13 (IP 64)), easy access for wiring, push button reset with memory, high immunity to strobe type and weld flash generated light and miniature design make the Model MG Safety Light Curtain easy to interface with all types of machine controllers and PLC’s. Extended scanning ranges are also available up to 75’ (23m). Also offered is a single/multiple floating beam blanking with indicator, single/multiple fixed beam blanking with indicator and auto blanking feature with indicator, built-in machine interface monitoring. Thirty standard light curtain sizes are available from 4” (102mm) to 120” (3048mm) lengths in 4” (102mm) increments. Made in USA..

Model DR Safety Light Curtains – Light curtain with DIN-rail mountable controller. Type 4 / Category 4, SIL 3, PL e. Made in USA.

Model DR Safety Light Curtains – Light curtain with DIN-rail mountable controller. Type 4 / Category 4, SIL 3, PL e. Made in USA.

Model CE Safety Light Curtains (Global) – A light curtain that can be supplied worldwide. Type 4 / Category 4, SIL 3, PL e. Made in USA.

Model CE Safety Light Curtains (Global) – A light curtain that can be supplied worldwide. Type 4 / Category 4, SIL 3, PL e. Made in USA.

Model CA (Cascading) Safety Light Curtains – Light curtains that can provide the user to connect multiple sets of light curtains (daisy chaining). Type 4 / Category 4, SIL 3, PL e. Made in USA.

Model CA (Cascading) Safety Light Curtains – Light curtains that can provide the user to connect multiple sets of light curtains (daisy chaining). Type 4 / Category 4, SIL 3, PL e. Made in USA.

Model PPG Perimeter Guarding Safety Light Curtains – Light Curtains that utilize wider beam spacing (arm/body detection) than light curtains that protect personnel from “pinch point” hazard zones. Type 4 / Category 4, SIL 3, PL.e. Made in USA.

Model PPG Perimeter Guarding Safety Light Curtains – Light Curtains that utilize wider beam spacing (arm/body detection) than light curtains that protect personnel from “pinch point” hazard zones. Type 4 / Category 4, SIL 3, PL.e. Made in USA.

Safety light curtains are opto-electronic safety devices used for machine safeguarding. Light curtains protect plant personnel by guarding the dangerous point of operation and nip points of industrial machinery. Our safety light curtain products offer low cost, more features, long product warranties and quick delivery. The light curtains’ safety classification is Type 4 / Category 4, SIL 3, PLe and are control reliable. Made in USA.

Pinnacle Systems designs, manufactures and provides service after the sale of our family/series of safety light curtains. When properly installed, a safety light curtain protects the machine operator and passerby by sending a series of invisible infrared light beams across an area to be guarded by determining whether or not the light beam(s) are blocked. Our safety light curtains have been time tested to be extremely dependable, feature intensive and to provide a cost effective solution for solving complex machine safeguarding projects while protecting your most valuable resource, the employee.

Our light curtains provide assurance to the employer and the machine operators that we can safely guard hazardous areas and the dangerous point of operation requirements of industrial machinery. Applications such as power press guarding and controls, press brake guarding, robot guarding and automation guarding are just a few examples of our safety light curtain machine safeguarding capabilities. Operator safety is our priority while effectively maintaining product quality which is backed by our long product warranties. Properly designed and interfaced light curtains can have an extremely positive end result on production throughput. We have also blended into our light curtain designs artificial intelligence (AI) for the light curtain system diagnostics for system faults that may arise over time. This is a great time saver and enhances the subject machines overall equipment efficiency (OEE) for the front line supervisor.

Pinnacle Systems is driven by creating safety light curtains that comply with or exceed OSHA (Occupational Safety and Health Association) and ANSI (American National Standards Institute) domestic safety standards and control reliability requirements. In addition, compliance with international machine guarding standards such as ISO, CSA and CE are recognized in our various models of light curtains.

If you have additional questions regarding our light curtain family, please do not hesitate to contact us directly!