Free standing two pylon 110 VAC input power system with built-in monitored safety relays (dry). Multiple beam spacing options are available for arm and body detection. Model PPG is designed for perimeter guarding applications and incorporates latching safety relays (dry) with mounted manual reset button on the receiver pylon. Long scanning distances available. Type 4 / Category 4. Made in USA.

Perimeter Guards utilize wider beam spacing than safety light curtains protecting personnel from “pinch point” or “point of operation” hazard zones. Perimeter Guards are designed to detect when an operator or passerby penetrates the perimeter of a hazardous zone. The Perimeter Guard safety light curtain will then initiate a stop signal to the machine control.

Perimeter Guards also incorporate latching safety relays. This requires a manual reset after each penetration into the guarded zone. This is an additional safety feature to protect the intruder from an inadvertent machine actuation while the intruder is within the work area.

• Power Requirements: 120VAC +/- 10% @ 50-60 Hz with fuse protection (24VDC units optional)

• Power Requirements: 120VAC +/- 10% @ 50-60 Hz with fuse protection (24VDC units optional)

• Power Consumption: 24 watts total

• Infrared Light Source: Solid state light emitting diodes

• Beam Spacing: Variable

• Response Time: Less than 30 milliseconds (All sizes)

• Relay Contact Ratings: 8 AMP rating @ 220VAC; 16 AMP rating @ 120VAC

• Relay Configuration: Dual captive contact self-checking safety relays.

• External Alphanumeric Diagnostic and Status Display

• Temperature Range: 32 degrees to 120 degrees F

• Scanning Frequency: 3.6 Khz

• Shock: Tested to withstand high vibration applications.

• Self-checking every 20 milliseconds.

• Indicators: Red obstruction light on receiver. Green non-obstruction light on receiver. Red alignment indicator light on emitter.

• Construction: Heavy duty aluminum enclosure (all welded). 14 Gauge – Dust and oil tight. NEMA 12

• Scanning Distance: All units are supplied standard with a 20′ (6.1m) scanning capability. Extended range units are available, consult your representative or the factory. Scanning distances must be specified — 90′ (27.432m) maximum.

• Specials: Custom designed light curtains for special applications. Examples: L-shaped, stainless steel. Consult factory.

• CSA Approved, UL Pending

• Three-Year Warranty

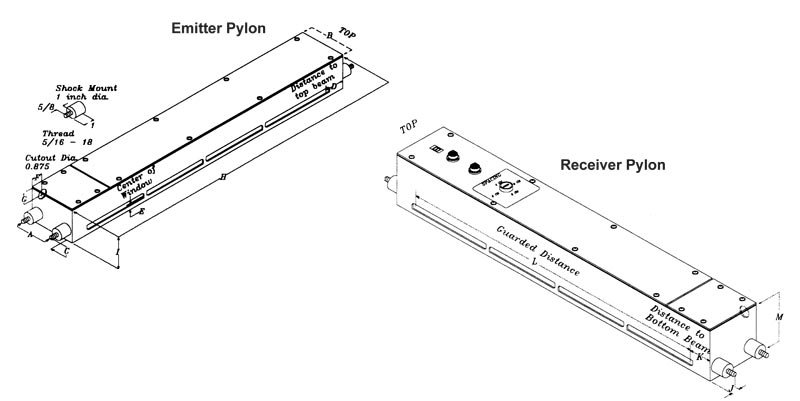

All Models

Dim A 3.00” (76mm)

Dim B 4.25” (108mm)

Dim C 1.00” (25mm)

Dim D 1.87” (48mm)

Dim E 0.62” (16mm)

Dim F 1.00” (25mm)

Dim G 1.00” (25mm)

Dim I 3.25” (83mm)

Dim J 0.62” (16mm)

Dim M 4.25” (108mm)

Dim H Dim K Dim L

Model (box length) (last to end) (first to last beam)

PPG-24 28.87” (733mm) 1.87” (48mm) 25.22” (641mm)

PPG-30 36.25” (921mm) 2.87” (73mm) 31.52” (801mm)

PPG-36 42.12” (1070mm) 2.87” (73mm) 37.82” (961mm)

PPG-42 48.37” (1229mm) 2.87” (73mm) 44.12” (1121mm)

PPG-48 54.75” (1391mm) 2.87” (73mm) 50.42” (1281mm)

PPG-60 67.25” (1708mm) 2.87” (73mm) 63.02” (1601mm)

PPG-72 79.75” (2026mm) 2.87” (73mm) 75.62” (1921mm)

PPG-84 91.75” (2330mm) 2.87” (73mm) 88.22” (2241mm)

PPG-96 103.75” (2635mm) 2.87” (73mm) 100.82” (2561mm)

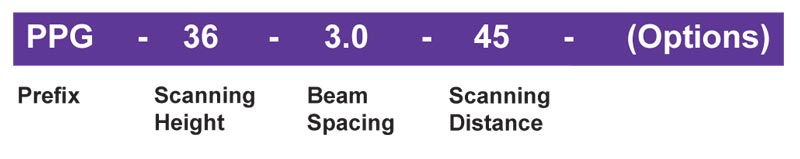

1. Specify height of unit

2. Specify beam spacing

3. Specify scanning distance — 100’ (30.4m) maximum

Pylon Sizes (Protected Area)

Inches: 24, 30, 36, 48, 60, 72, 84, 96

Millimeters: 609.6, 762, 914.4, 1219.2, 1524, 1828.8, 2133.6, 2438.4

Beam Spacing

1.5 – 1.5” (38.1mm) Spacing of Beams

3.0 – 3.0” (76.2mm) Spacing of Beams

6.0 – 6.0” (152.4mm) Spacing of Beams

12.0 – 12.0” (304.8mm) Spacing of Beams

Options

Auxiliary Output Contact. Provides an isolated (dry) contact output to be used as a signal line. Specify N.O. or N.C. output. Add suffix AO to light curtain Model Number.

External Relay Check. This option monitors the control relays of the guarded machine to assure that the machine control relays change state when the safety light curtain sends a stop signal. Add suffix ER to light curtain Model Number.

24VDC Power Source. Add suffix DC to light curtain Model Number.

32-108 – High Load Safety Relay – 110 VAC

20 AMP high load safety relay incorporates a 110 VAC coil with 3 NO (held closed) and 1 NC contact. Each light curtain requires two relays. Dimensions: (45mm width x 91mm length x 85mm height)

32-109 – High Load Safety Relay – 24vdc

20 AMP high load safety relay incorporates a 24vdc coil with 3 NO (held closed) and 1 NC contact. Each light curtain requires two relays and EDM feature. Dimensions: (45mm width x 91mm length x 115mm height)

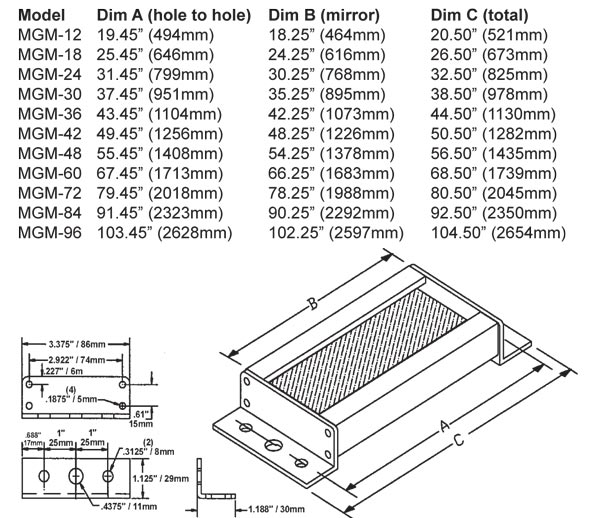

Cornering Mirrors

Through the use of cornering mirrors, multiple sides or work envelopes can be guarded which enhance safety and reduce downtime related to mechanical and electrical interlock systems. Include a 5% reflectivity loss per mirror when calculating the total scanning distance of the light curtain.

For the Model PPG, please replace MGM with TRM.

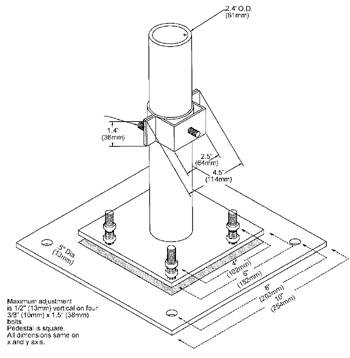

Pedestal Dimensions

The heavy duty, all welded steel pedestal floor mounts can be used for mounting either light curtain pylons or cornering mirrors. Sliding mounts on the pedestal are of universal design and are supplied standard. Unique floating base on pedestal is designed to compensate for uneven floors.

The heavy duty, all welded steel pedestal floor mounts can be used for mounting either light curtain pylons or cornering mirrors. Sliding mounts on the pedestal are of universal design and are supplied standard. Unique floating base on pedestal is designed to compensate for uneven floors.

NOTE: Pedestals must be bolted to the floor, they must not be movable (ANSI B11.19-2010).

1. Sliding mounts supplied

2. Standard height is 72” (1829mm) – Model #8000

Optional 96” (2438mm) – Model #8096

3. Painted OSHA yellow

4. Pedestal is 12 gauge steel

Base Plate is 1/4” (6.35mm) steel plate

Ordering Procedure

Specify Pedestal Model Number and Quantity

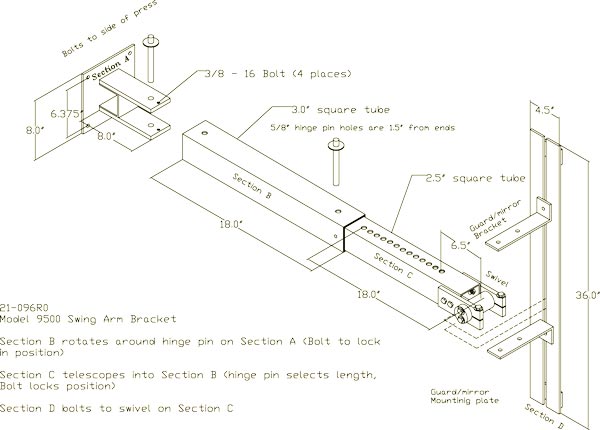

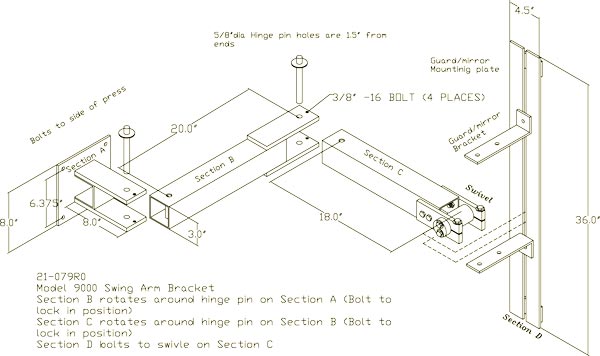

Model 9000 and 9500 Mounting Brackets

Excellent method of mounting the light guard for press brakes or when the light guard is to be moved for die setups or machine maintenance. Model 9000 consists of three 180-pivot points along with light guard diagonal movement capability for virtually unlimited light guard positioning. Two-inch square tubing 3/16” thick painted OSHA yellow which mounts directly onto the machine housing and makes for a heavy duty yet versatile mounting bracket. Model 9500 consists of two 180-pivot points and one adjustable length arm.

Model 9000

Model 9500