Ergonomic palm buttons are machine operator activation devices that eliminate the force, position and pressure required to activate an industrial machine when compared to the old style and high pressure spring loaded mechanical palm buttons. Our unique design requires no force or pressure and safely maintains the premier ergonomic position of neutral, 0° deviation and maintains 100% hand power for the machine operator. This premier ergonomic product can reduce or eliminate the harmful effects of carpal tunnel syndrome and other ergonomic maladies caused by high pressure spring loaded mushroom palm buttons. Product manufacturer and Made in USA.

UL-101-2P and UL-101-4P (24VDC) Installation Sheet

UL-101-2P and UL-101-4P (110VAC) Installation Sheet

Model 8500 T Stand Dimensions

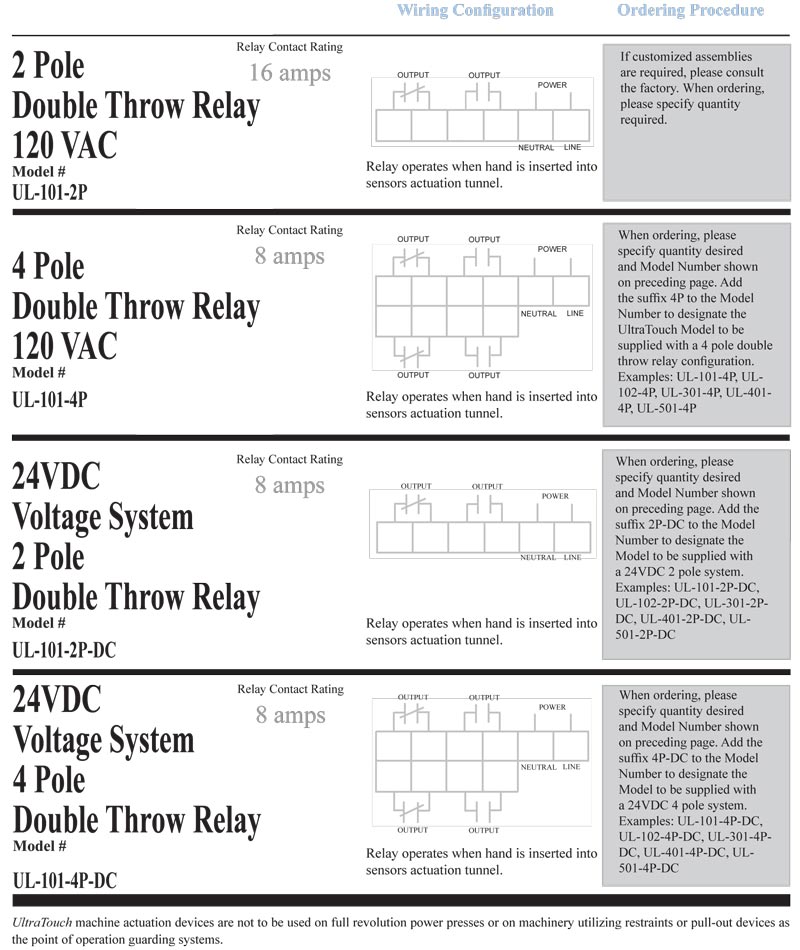

UL-101-2P

UL-101-2P

One UltraTouch module–Direct replacement into most existing operator stations into existing mechanical palm buttons space and screw configurations. Excellent for retrofit projects.

UL-102-2P

UL-102-2P

One UltraTouch module with a complete self-contained NEMA 12 enclosure. Dimensional configuration of NEMA 12 enclosure of 3.50” (89mm) x 6.375” (162mm) x 2.95” (75mm). Excellent for installations when the UltraTouch system must be mounted individually due to space limitations.

UL-301-2P

UL-301-2P

Two UltraTouch modules mounted on a NEMA 12 operator station run bar. The UltraTouch modules are mounted in accordance to OSHA, ANSI, and CSA standards in regards to run button spacing.

UL-401-2P

UL-401-2P

Two UltraTouch modules mounted on a NEMA 12 operator station run bar with a red mushroom emergency stop button located in the center. Excellent for installations requiring an emergency stop button for the operator. All the modules are mounted in accordance to OSHA, ANSI, and CSA standards in regards to run button spacing.

UL-501-2P

UL-501-2P

Two UltraTouch modules mounted on a NEMA 12 operator station run bar with a red mushroom emergency stop button located in the center and a yellow mushroom top button located off center. Ideal for the metal stamping/metal fabrication industry. All the modules are mounted in accordance to OSHA, ANSI, and CSA standards in regards to run button spacing.

UL-601 (Specify AC or DC as suffix to Model Number)

UL-601 (Specify AC or DC as suffix to Model Number)

Anti-tie down/concurrent operation module. This assembly supplies the control that, when added to two UltraTouch devices, assures that the operator occupies both hands and must initiate both UltraTouch devices within a preset period of time. The anti-tie down/concurrent module comes in a NEMA 12 enclosure and can be added to any of the styles. NEMA 12 enclosure 6” (152mm) x 8” (203mm) x 6” (152mm). This is required on all machines that do not have this capability in the machine control. (Available without control box. Part #UL-601-NB module. Requires 4” (102mm) x 5” (127mm) space.)

8500

8500

The Model 8500 adjustable pedestal mount can be utilized for mounting the operator stations or the UltraTouch modules off the machine. These adjustable height pedestals are painted OSHA yellow and are of heavy angle construction with a floor mounting plate that can be lagged to the floor. The adjustable height feature assures the correct ergonomic position for various size operators. This will help control stretching and pulling strains of the operator.

Specifications

| NEMA 4 Sealed Housing Solid State Circuitry Dual Sensor Sources–Infrared/Capacitive Response Time <20 ms CSA Approved, UL Listed Module requires a 2” (51mm) mounting depth in run bar Current Requirements 110 VAC: 2 pole — 50 mA | 4 pole — 60 mA 24 VDC 2 pole — 150 mA | 4 pole — 250 mA |

Operator Status Indicator — LED’s A. Red — Ready to cycle B. Green — Cycle initiated Relay Type — Captive Contact Safety Relay Relay Rating — 8 amp @ 220 VAC; 8 amp @ 120 VAC Relay Cycle Life Mechanical — 50 million cycles Electrical — 100,000 cycles at 220 VAC, 4 amp Voltage Range — +/- 10% Warranty — 2 years |

Ordering Procedure