Ensuring workplace safety is a top priority in industrial settings, and machine guarding plays a critical role in protecting workers from hazardous machinery. However, failing to comply with OSHA standards can result in severe injuries, costly fines, and operational disruptions.

Each year, OSHA issues thousands of citations related to inadequate or missing machine guards, placing machine guarding violations among the most common workplace safety infractions. Understanding these violations and implementing proper solutions can help facilities maintain compliance, improve safety, and avoid costly penalties.

This guide explores the five most common OSHA machine guarding violations, their consequences, and how to prevent them using the right safety measures.

Understanding OSHA Machine Guarding Requirements

OSHA’s 29 CFR 1910.212 outlines the general requirements for machine guarding, stating that machines must be safeguarded to prevent worker injury from moving parts, flying debris, or other mechanical hazards.

Key OSHA Machine Guarding Standards:

- 29 CFR 1910.212 – General requirements for all machines.

- 29 CFR 1910.213 – Woodworking machinery requirements.

- 29 CFR 1910.217 – Mechanical power press safety.

- 29 CFR 1910.219 – Requirements for belts, pulleys, and rotating parts.

Types of Guards Recognized by OSHA:

- Fixed Guards – Permanent barriers that enclose hazardous areas.

- Interlocked Guards – Shut down machines when access points are breached.

- Adjustable Guards – Allow flexibility while maintaining protection.

- Self-Adjusting Guards – Automatically reposition to protect operators.

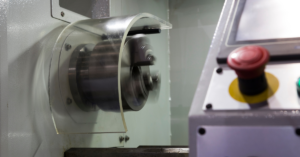

1. Inadequate or Missing Guards

One of the most cited OSHA violations involves machinery that lacks proper guarding, leaving workers exposed to hazardous moving parts.

Common Causes of This Violation:

- Failure to install guards on new equipment.

- Workers removing guards for maintenance and not replacing them.

- Using makeshift guards that don’t meet OSHA standards.

Example:

A manufacturer was fined $75,000 after OSHA found multiple machines operating without guards, exposing workers to rotating parts and flying debris.

How to Avoid This Violation:

- Ensure all machines have appropriate guards installed before use.

- Conduct regular inspections to verify guards are in place and functioning.

- Train employees on the importance of machine guarding and the risks of removing safety barriers.

Recommended Solution: Install interlock switches on gates and enclosures to prevent access to hazardous areas while machines are in operation.

2. Improper Use of Safety Devices

OSHA requires that machine guards remain securely in place and that safety devices, such as safety light curtains and emergency stops, function correctly. However, many facilities fail to properly implement or maintain these systems.

Common Issues Leading to Violations:

- Bypassing safety devices to speed up production.

- Failing to integrate safety systems with machinery controls.

- Using outdated or non-functioning safety devices.

Example:

A facility received an OSHA citation after disabling an interlock switch to increase production speeds, leading to a serious worker injury.

How to Avoid This Violation:

- Use fail-safe safety devices, such as safety mats and interlocks.

- Regularly test and maintain safety devices to ensure they function properly.

- Train employees on the importance of never bypassing safety systems.

Recommended Solution: Use programmable safety controllers to monitor and manage multiple safety devices, ensuring seamless machine operation.

3. Lack of Guarding on Power Transmission Components

OSHA mandates that belts, chains, gears, pulleys, and rotating shafts be properly guarded to prevent entanglement hazards. However, many facilities overlook guarding these components.

Common Causes of This Violation:

- Failing to install covers on rotating machinery.

- Removing guards for maintenance and not reinstalling them.

- Using improper guarding materials that deteriorate over time.

Example:

A worker lost a finger after getting caught in an unguarded conveyor belt pulley. The company was fined $85,000 for failing to provide proper guarding.

How to Avoid This Violation:

- Install fixed guards on power transmission parts.

- Ensure all belt and chain drives have protective covers.

- Inspect guards regularly to check for damage or loose fittings.

Recommended Solution: Use custom fencing systems with proper mesh sizes and finishes to enclose power transmission components safely.

4. Failure to Provide Proper Training

A lack of employee training on machine safety is a major contributor to workplace injuries and OSHA violations.

Common Issues Leading to Violations:

- Employees operating machinery without proper knowledge.

- New hires not receiving adequate safety training.

- Lack of refresher courses for experienced workers.

Example:

OSHA penalized a company after an untrained employee bypassed a safety device, leading to a severe hand injury.

How to Avoid This Violation:

- Conduct regular safety training guarding principles.

- Implement hands-on safety drills for employees working with hazardous equipment.

- Require annual refresher courses on compliance.

Recommended Solution: Use safety training programs to educate employees on proper guarding practices and workplace safety.

5. Failure to Conduct Regular Inspections

OSHA requires that guards be regularly inspected and maintained to ensure they function properly. Many facilities fail to conduct inspections, leading to worn-out or missing guards.

Common Causes of This Violation:

- Lack of scheduled machine safety audits.

- Ignoring wear and tear on machine guards.

- Failing to replace or repair damaged guards.

Example:

A company was cited for OSHA violations after an inspection revealed broken safety guards on several machines, increasing the risk of severe injuries.

How to Avoid This Violation:

- Establish a routine inspection schedule for all machine guarding equipment.

- Assign safety officers to check guard integrity and function.

- Replace worn-out guards immediately to prevent worker exposure.

Recommended Solution: Implement preventive maintenance programs to ensure guards remain in optimal condition.

Best Practices for OSHA Compliance

To avoid OSHA violations, facilities should adopt a proactive approach to safety. Here are the best practices to ensure compliance:

1. Implement a Machine Guarding Policy

- Establish clear guidelines.

- Require management approval for any guard removal.

2. Use the Right Guarding Products

- Install safety light curtains for enhanced protection.

- Use interlock switches on access gates.

- Integrate safety mats for immediate hazard detection.

3. Conduct Safety Audits and Inspections

- Perform routine safety audits to check machine guarding effectiveness.

- Keep detailed records of inspections and maintenance.

Final Thoughts on OSHA Compliance

Avoiding OSHA violations requires a proactive safety strategy that includes proper installation, employee training, and regular maintenance. By implementing effective solutions, businesses can protect workers, avoid fines, and maintain productivity.

For high-quality safety light curtains, safety mats, and interlock switches, explore Pinnacle Systems’ machine guarding solutions.