Cascading safety light curtains provide the user the ability to connect additional sets of light curtains by daisy chaining multiple emitters and receivers together rated Nema IV (IP 65). The cascading of safety light curtains provides multiple areas of guarding in any plane (X, Y, Z), while utilizing the control reliable dual safety outputs (PNP) from the Category 4 safety device for the safety outputs to the machine control. The ability to guard multiple areas on irregular shaped machines by cascading safety light curtains reduces wiring and provides a lower cost yet effective machine guarding solution. 24VDC input powered unit. Mounting brackets and connecting cables are supplied standard. Type 4 / Category 4. Made in USA.

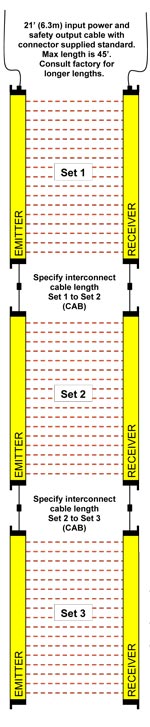

Cascading safety light curtains provide the user the ability to connect additional sets of light curtains by daisy chaining multiple emitters and receivers together. The interconnecting cables are factory supplied and the user defines length. The cascading of safety light curtains provides multiple areas of guarding in any plane (X, Y, Z), while utilizing the control reliable dual safety outputs from the Category 4 safety device for the safety outputs to the machine control. The ability to guard multiple areas on irregular shaped machines by cascading safety light curtains reduces wiring and provides a lower cost yet effective machine guarding solution.

Cascading safety light curtains provide the user the ability to connect additional sets of light curtains by daisy chaining multiple emitters and receivers together. The interconnecting cables are factory supplied and the user defines length. The cascading of safety light curtains provides multiple areas of guarding in any plane (X, Y, Z), while utilizing the control reliable dual safety outputs from the Category 4 safety device for the safety outputs to the machine control. The ability to guard multiple areas on irregular shaped machines by cascading safety light curtains reduces wiring and provides a lower cost yet effective machine guarding solution.

The Model CA Cascading Safety Light Curtain is an infrared safety light curtain that is designed to the IEC 61496 standard. When properly installed, it protects the machine operator by passing an invisible infrared light beam across an area to be guarded and examining whether or not the light beam(s) are blocked. If the light beam(s) are blocked, monitored solid state outputs will open, issuing a “STOP” command to the machines normally closed (N.C.) “STOP” circuit. The Model CA Cascading safety light curtains system is composed of transmitting units (EMITTERS), and receiving unit (RECEIVERS). The entire system is control reliable Category 4 (per IEC 61496). A single fault anywhere within the Model CA will not prevent at least one of the solid state outputs from opening up, (allowing a “STOP” command) when either a beam is broken or an internal fault occurs.

Theory of operation.

The Model CA Cascading Safety Light Curtain protects an area by projecting a curtain of infrared light. The infrared emitters and receivers face each other across the field to be protected. Each LED pair is spaced along the length of the pylons at regular intervals from .5” (12mm), up to 8” (203mm) depending on the application. The smaller spacing are for finger guarding, the larger spacing are for body protection. The emitter/receiver pairs are scanned sequentially (one at a time) by a very short pulse of infrared light starting from bottom (cable end), and working up to the end, until every beam pair has been scanned. Two 16 bit computers in the first emitter pylon and two 16 bit computers in the first receiver pylon control the operation, as well as cross check each pylon.

The System.

The Model CA Cascading Safety Light Curtains employ infrared technology in a small sealed NEMA 4 (IP 67) aluminum housing with an infrared passing (daylight filtering) acrylic lens. This system provides harmless invisible protection and an unobstructed view of the guarded area. There are two parts to the Model CA: An Emitter pylon and a Receiver pylon. The Emitter pylon has no outputs. The Receiver pylon contains two monitored solid state 24vdc outputs. Both pylon sets are synchronized to each other electronically as they are connected together with the interconnect cables to the top and bottom of the next set of pylons.

System Safety.

The Model CA Cascading Safety Light Curtains incorporates redundant, and diverse technology that provides a backup for every system that could cause an unsafe condition.

External Device Monitoring (EDM).

A method in which the Model CA Category 4 cascading safety light curtains logic monitors the state of various external control devices. The control devices are external and not part of the Model CA light curtain pylons. A lockout or stop signal will result if an unsafe state is detected in an external device. The External Device Monitoring (EDM) is an optional function of the Model CA safety light curtain for monitoring the status of external devices such as gate and door switches, safety switches or the main control element of the drive (MPCE). Solid state outputs are turned on separately to be checked and to assure neither output has been shorted, before fully turning on.

Design Criteria.

Designed to meet IEC 61496-1 & 2, UL 1998, UL subject 491, OSHA, ANSI, CSA, ANSI-RIA R15.06-2012

Safety Category 4 (EN 954-1)

SIL 3 (EN 61508)

Performance Level PL e (ISO 13849-1)

Microprocessor redundancy for both Emitter and Receiver pylons

Redundant, monitored, 24vdc solid state outputs (PNP)

Watchdogs on CPU’s and outputs prevent unintentional output during lockups.

Remote Status Display

The optional Remote Status Display (RSD) may be used in conjunction with the Model CA Cascading Safety Light Curtains. The RSD provides the machine operator and front line supervisor immediate system status and diagnostics when the Model CA is mounted inside the machine control panel. The RSD also controls all blanking options directly from the panel location where it is installed.

Remote Status Display (RSD) Components:

• Red/Green/Yellow indicator lights

• Diagnostic scrolling message display with 5’ (1.5m) of connector cable

• Keyed selector switch and yellow blanking active indicator supplied if blanking is used

• Customized Blanking Available

The RSD components are mounted on a steel plate and are designed to be exterior panel mounted. The RSD option enhances safety and is a time saver at machine set-up and when maintenance diagnostics are required.

Cincinnati Interface

Description: The Cincinnati Interface is provided to allow an external device to determine if the light curtain is still capable of shutting down the safety control circuit. The Cincinnati Interface allows an external device to override the light curtain and initiate a RED condition and open up the standard output relay contacts.

Application: Cincinnati Press, PLC

• Manual Latching Relay Provision

Blanking Options

Floating Blank – (8K) Option

The “Floating Blank” option provides the flexibility necessary to effectively guard all types of equipment that require multiple floating beams. This is quite common in the fabricating industry where the work piece moves.

The “Floating Blank” permits work pieces to be formed vertically or horizontally through the guarded area without shutting down the machine. Entry into the protected area by the operator or passerby will prevent the start or, if the machine is in motion, will provide a signal to stop the machine.

The “Floating Blank” is controlled by a keyed selector switch that will allow a work opening of 2” (51mm) based on 1/2” (13mm) increments. This information is displayed on the message display of the controller. Blanking adjustments required when die heights change are not necessary. The “Floating Blank” light curtain automatically adjusts to the various feed positions providing production with protection.

The “Floating Blank” (8K) Option includes:

–1/2” (13mm) – Constant scan light curtain

–1” (25mm) – One floating beam

–1 1/2” (38mm) – Two floating beams

–2” (51mm) – Three floating beams

Auto-Blanking – (AB) Option

The advanced “Auto Blank” option is unique because it will automatically blank out only the required number of beams needed to accept an obstruction such as a conveyor, bracket, or fixture. The unit is easily programmed by a supervisory controlled four-position keyed selector switch located on the front panel of the RSD Display. The “Auto Blank” method of blanking is much safer than DIP switch or master/slave blanking systems because only the areas of the obstruction will be blanked. This feature prohibits unsafe oversizing of the blanked area commonly found throughout the industry on manually blanked systems. “Auto Blank” also eliminates the need to count beams and to locate where and what beams are to be shut off to obtain the correct beam elevation to accept an obstruction. This information is displayed on the message display of the controller. “Auto Blank” will also watch the obstruction and, if it moves or is removed, will go into a “machine stop mode” to prevent further machine operation. This is an additional safety feature not available on manually blanked units. These features truly enhance production while providing the ultimate in safety.

When the key switch is turned to the “Auto Blank” function, the “External Diagnostic Message Display” will show the number of blocked beams and where the obstruction is in the light curtain, then verify that the obstruction is being monitored. This is required information for the depth penetration factor and for proper installation of any safety light curtain. Learned Auto Blank patterns for the Model CA are stored in non-volatile memory for automatic recall at power-up.

The versatile “Auto Blank” (AB) blanking series includes:

• Constant scan light curtain

• One beam floating blank built-in plus “Auto Blank” capability

• Two “Auto Blank” modes – up to 4” blanked out (larger sizes available upon request) but need not be sequential

A. One “Auto Blank” mode with keyed reset when guarded zone is penetrated (latch)

B. One “Auto Blank” mode with automatic reset when guarded zone is penetrated

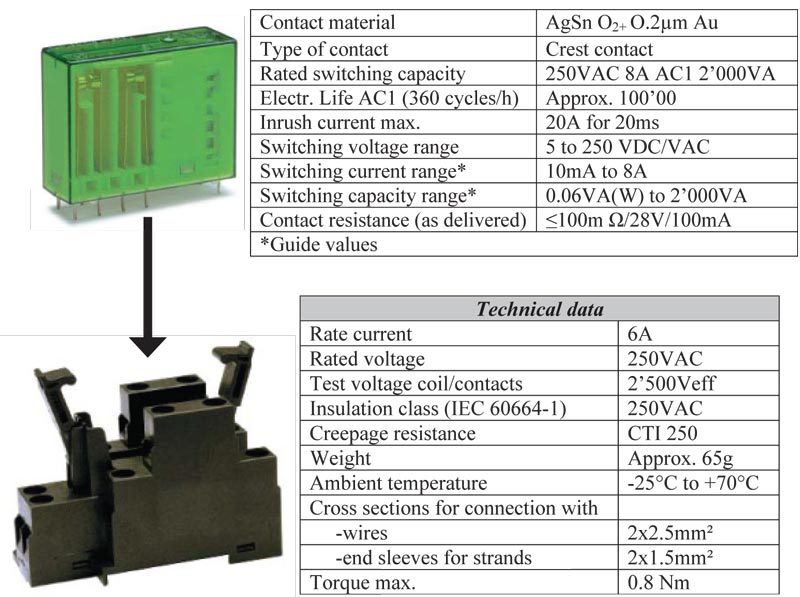

Safety Relay and Socket Assembly or SSSR Safety Relay Interface

Safety Relay — Part #52-278 (Two Required)

DIN-Rail or Back Plate Mounting

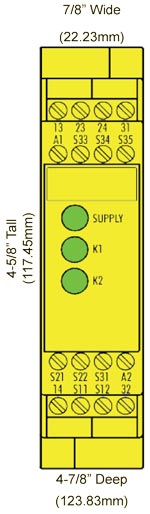

SSSR Safety Relay Interface

Part # SSSR

Allows customer selectable Manual or Auto Reset. Fits in a smaller space than two 52-278 safety relays.

Basic device for Emergency-Stop and Safety Gate Applications

Basic device for Emergency-Stop and Safety Gate Applications

–Basic device to EN 60204-1:2005 and EN ISO 13849:2007 for single or dual E-stop monitoring.

–PL e / category 4 in accordance with EN ISO 13849-1:2007 (previously EN 954:1997 category 4)

–SILCL 3 in accordance with EN 62061:2005

–Stop category 0 acc. EN 60204-1

–Manual or automatic start

–Cross monitoring

–Feedback loop to monitoring external contactors

–2 Enabling paths, 1 signalling path

–Processing of signals from output switching devices (OSSD) of light curtains acc. EN 61496-1.

–To connect to load side of safety mats acc. EN 1760-1

–Debouncing of inputs

Description of Device and Function

SSSR – This device is a two-channel safety switching device for emergency stop applications

with self-monitoring on each ON-OFF cycle. It conforms to EN 60204-1 and is equipped with positively

driven relays.

Basic function: After supply voltage has been connected to terminals A1/A2 and the safety inputs

closed, operating the reset button closes the enabling current paths (manual start). When the safety

inputs are opened/de-excited the enabling current paths will open.

• Input Power: Emitter pylon: 24vdc @ .125A

Receiver pylon: 24vdc @ .125A (solid state outputs are PNP which may draw up to .25A additional)

• Internal fuses: Emitter Pylon: F1 @ 1A

Receiver Pylon: F1 @ 1A, F2 @ 1/2A, F3 @ 1/2A

• Outputs: Receiver pylon: monitored, 2 outputs, solid state PNP (.5A maximum each output) (24vdc when GREEN, float when RED/off). Max .25A draw each.

• Indicators: Emitter pylon: Yellow, Red, Green.

Receiver pylon: Yellow, Red, Green.

• Construction: Painted aluminum extrusion with Acrylic IR lens and Viton Seals providing NEMA 14 (IP 65) protection.

Optional Polycarbonate tubes (sleeves) over the pylons provides NEMA 4 (IP 65) protection.

Emitter pylon: Four conductor 24AWG

Receiver pylon: Six conductor 24AWG

Pylons: Yellow | Cables: Black

• Temperature: 0 to 50c (up to 95% humidity, non-condensing)

• Safety Software: 0 to 50c tested to UL1998 and ISO 9001 standards.

• Pylon Enclosures: Tested to IEC 60529

• EMC Testing to IEC 61000-4 standards.

• Dimensions: 1.45” (36.8mm) square X selected length (see tables for lengths)

• Beam Spacing & Minimum Object Sensitivity (MOS)

.5” (12.7mm) .55” (14mm) MOS

1” (25.4mm) 1.18” (30mm) MOS

(special order, 4” active area followed by a 4” or 8” gap)

• Response Time and Scanning Frequency: < 30 mSec total, 10 khz

• Shock: Tested to withstand high vibration (using shock mounts)

• Self-Checking: Every 15mSec

• Scanning distance

From 1’ to 20’ standard (1-6m)

From 21’ to 75’ (6-22.8m) extended range (optional)

The range is stated as a two digit number within the Model #

• Specials: Custom designed light curtains for special applications. Consult factory.

• Surface Mount Technology

• One Year Warranty

• Made in USA

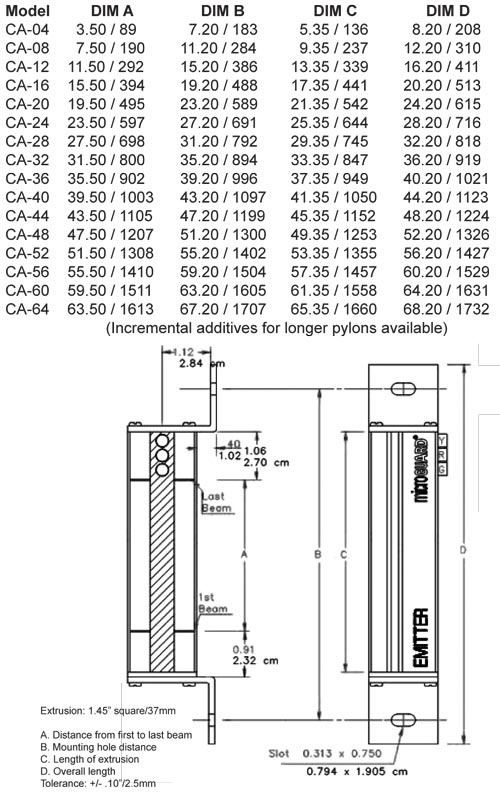

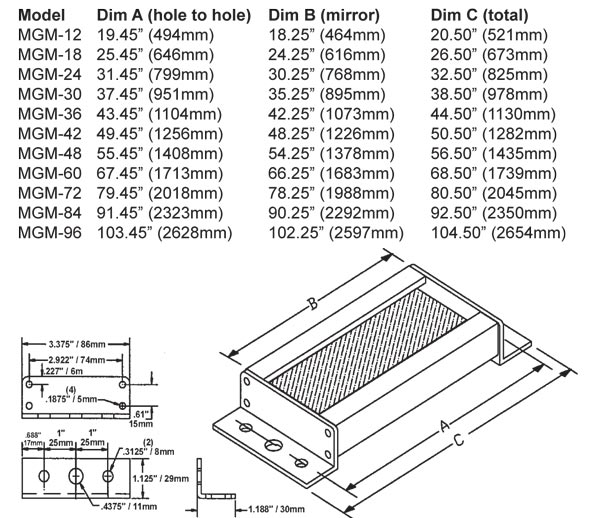

Pylons with Fixed Mounting Brackets (in/mm)

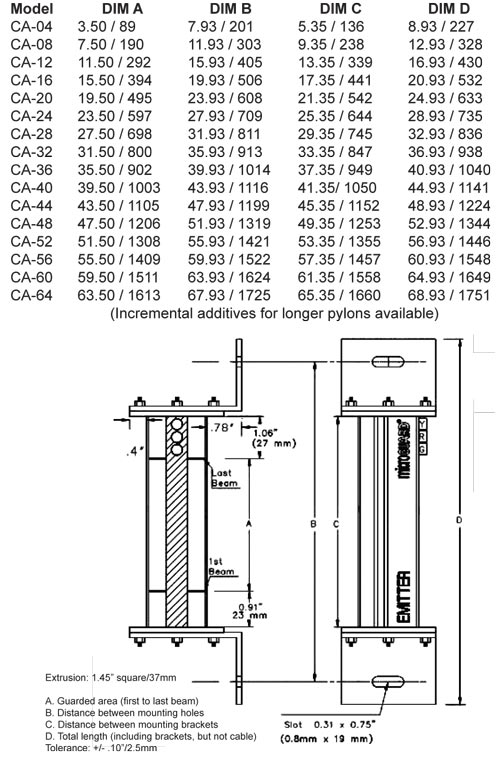

Pylons with Swivel Mounting Brackets (in/mm)

Model CA Output Circuits must be used with either “Control Reliable” PLC Safety Input Circuits or a Safety Relay Module.

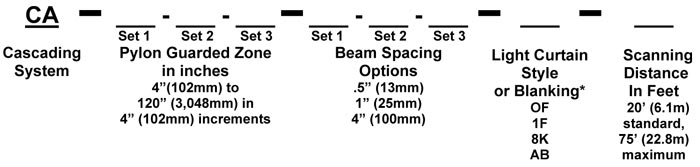

*Light Curtain Style or Blanking Description

OF – Constant scan – no blanking

1F – 1 beam floating blank built-in.

8K – Up to 3 beam floating blank adjustable by the use of a supervisory keyswitch removable in all positions. Capable of constant scan or one, two or three floating beams.

(Requires RSD option)

AB – Includes constant scan light curtain, one beam floating blank and two auto blank modes.(Requires RSD option)

If modifications are needed, please consult factory.

Options

SMB – Swivel Mounting Brackets for Pylons: Replaces the fixed mounting brackets normally supplied. Provides a 360° rotation of pylons.

PT – Polycarbonate tube which will encase the pylons for high impact protection.

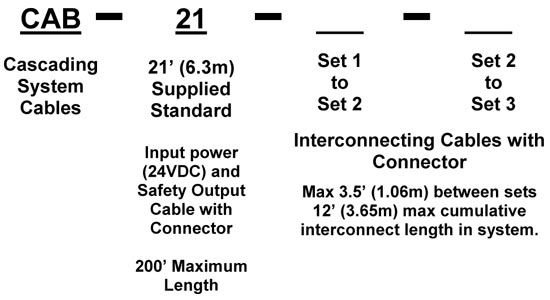

Ordering/Pricing Procedure for Cables

Please note that both the Pylons and Cables part numbers must be submitted to complete the order.

- Pylons can be hard wired together with no connectors if required (consult factory).

- Maximum of 128 beams per system (cumulative).

- Consult factory for larger beam systems or additional segments if needed.

Cornering Mirrors

Through the use of cornering mirrors, multiple sides or work envelopes can be guarded which enhance safety and reduce downtime related to mechanical and electrical interlock systems. Include a 15% reflectivity loss per mirror when calculating the total scanning distance of the light curtain.

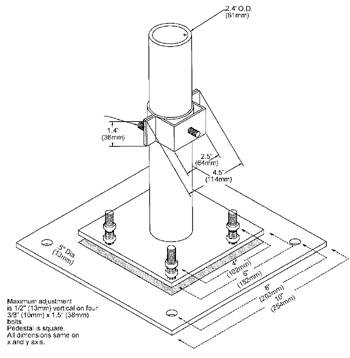

Pedestal Dimensions

The heavy duty, all welded steel pedestal floor mounts can be used for mounting either light curtain pylons or cornering mirrors. Sliding mounts on the pedestal are of universal design and are supplied standard. Unique floating base on pedestal is designed to compensate for uneven floors.

The heavy duty, all welded steel pedestal floor mounts can be used for mounting either light curtain pylons or cornering mirrors. Sliding mounts on the pedestal are of universal design and are supplied standard. Unique floating base on pedestal is designed to compensate for uneven floors.

NOTE: Pedestals must be bolted to the floor, they must not be movable (ANSI B11.19-2010).

1. Sliding mounts supplied

2. Standard height is 72” (1829mm) – Model #8000

Optional 96” (2438mm) – Model #8096

3. Painted OSHA yellow

4. Pedestal is 12 gauge steel

Base Plate is 1/4” (6.35mm) steel plate

Ordering Procedure

Specify Pedestal Model Number and Quantity

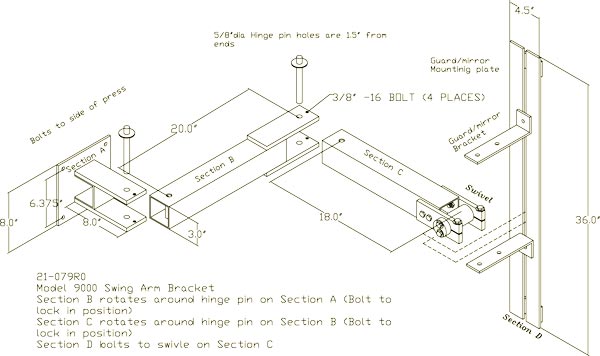

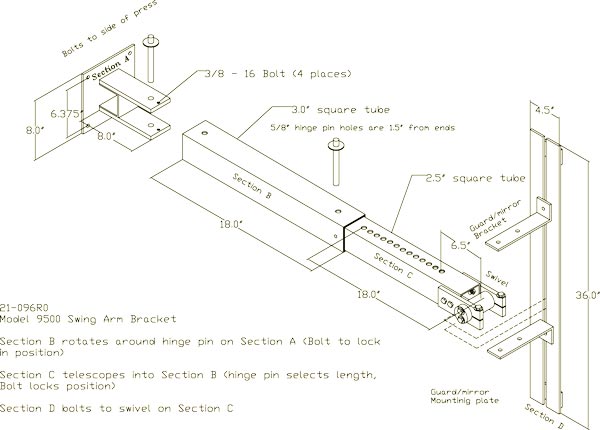

Model 9000 and 9500 Mounting Brackets

Excellent method of mounting the light guard for press brakes or when the light guard is to be moved for die setups or machine maintenance. Model 9000 consists of three 180-pivot points along with light guard diagonal movement capability for virtually unlimited light guard positioning. Two-inch square tubing 3/16” thick painted OSHA yellow which mounts directly onto the machine housing and makes for a heavy duty yet versatile mounting bracket. Model 9500 consists of two 180-pivot points and one adjustable length arm.

Model 9000

Model 9500

Part # 11-183: Two piece adjustable mounting bracket for pedestals (with one mounting stud 5/16”-18 stud). Stainless Steel (for Mirror and Guard pylon) (Two required per pedestal) Part # 11-183: Two piece adjustable mounting bracket for pedestals (with one mounting stud 5/16”-18 stud). Stainless Steel (for Mirror and Guard pylon) (Two required per pedestal) |

Part # 11-184: Two piece adjustable mounting bracket for pedestals (with one mounting stud 5/16”-18 studs 90 degrees apart). Stainless Steel (for Guard at one corner) (Two required per pedestal) Part # 11-184: Two piece adjustable mounting bracket for pedestals (with one mounting stud 5/16”-18 studs 90 degrees apart). Stainless Steel (for Guard at one corner) (Two required per pedestal) |

Part # 11-199: Two piece adjustable mounting bracket for pedestals (with two mounting studs 5/16”-18 studs 180 degrees apart). Stainless Steel (for multiple Guards mounted side by side) (Two required per pedestal) Part # 11-199: Two piece adjustable mounting bracket for pedestals (with two mounting studs 5/16”-18 studs 180 degrees apart). Stainless Steel (for multiple Guards mounted side by side) (Two required per pedestal) |

Polycarbonate Tube: Optional Polycarbonate tube which will encase the pylons for high impact protection. Polycarbonate Tube: Optional Polycarbonate tube which will encase the pylons for high impact protection. |