Safety Light Curtain Model DR has a DIN-rail mountable controller rated NEMA 1 (IP 10) for mounting into an existing control panel and the pylons are rated Nema 4 (IP 65). Input power is 24VDC. Complete system diagnostics, blanking capability, mounting brackets and connecting cables are supplied standard. Type 4 / Category 4. Made in USA.

–Meets or exceeds OSHA, ANSI, CSA, RIA, CE standards, UL Subject 491, UL1998, IEC 61496 standard parts 1 and 2

–Meets or exceeds OSHA, ANSI, CSA, RIA, CE standards, UL Subject 491, UL1998, IEC 61496 standard parts 1 and 2

–Snap-out wiring terminals reduce both installation and maintenance time

–Universal controller for all pylon sizes

–Small and compact DIN-rail Mountable Controller

–Small and compact safety light curtain Model DR pylons

–Multiple status indicators for operator awareness

–Quick disconnect wiring at pylons

–Largest selection of sizes available

–Largest selection of options available

–Multi-lingual diagnostic display available

–Diverse redundant design concept

–Utilizes captive contact force-guided safety relays

–Largest selection of blanking options available—fixed or floating blanking

–Patented “auto blank” capable controller

–Remote status display (RSD) capable

–Diagnostic message display built-in

–External relay checking built-in

–Emergency stop input built-in

–Auxiliary relay output built-in

–Fault relay output built-in

–Remote latching reset built-in

–Remote indicator lights output provision built-in

–Push button reset with memory

–Analog output for non-safety related applications (optional) -10v to +10v or 0 to +10v (consult factory)

–Two-year warranty on the Safety Light Curtain Model DR

–Made in the USA

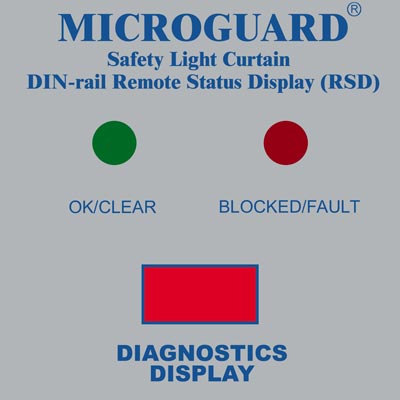

The optional Remote Status Display (RSD) may be used in conjunction with the MicroGuard DIN-rail Controller. The RSD provides the machine operator and front line supervisor immediate system status and diagnostics when the DIN-rail Controller is mounted inside the machine control panel. The RSD can also control all blanking options if that style light curtain is used.

Remote Status Display (RSD) Components:

–Red/Green/Yellow indicator lights

–Diagnostic scrolling message display with 5’ (1.5m) of connector cable

–Keyed selector switch and yellow blanking active indicator supplied if blanking is used

–Customized Blanking Available

The RSD components are mounted on a steel plate and are designed to be exterior panel mounted. The RSD option enhances safety and is a time saver at machine set-up and when maintenance diagnostics are required.

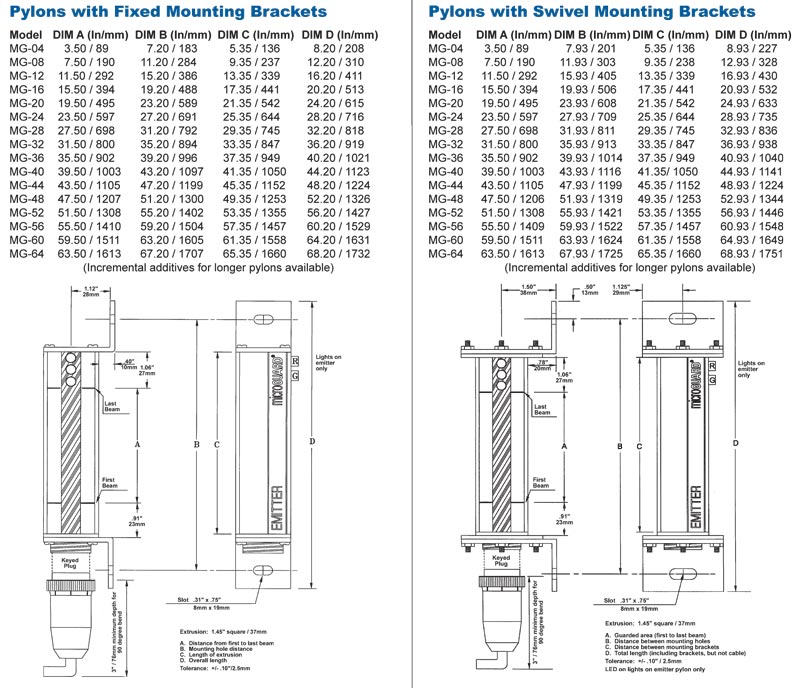

Pylons:

• Heavy duty aluminum extrusion NEMA IV (IP 65)

• Replaceable infrared lens cover (acrylic)

• Sealed bulkhead positive locking circular connectors

• Mounting brackets supplied standard

• Emitter pylon – red/green/yellow status indicators

Cables:

• Shielded PVC 22 AWG cables with quick disconnects

and strain relief fittings

• Emitter cable – 20’ (6.1m) supplied standard for the Metal Box Controller Module and 22’ (6.7m) supplied standard for the DIN-rail Controller Module (Safety Light Curtain Model DR)

• Receiver cable – 8’ (2.44m) supplied standard for the Metal Box Controller Module and 22’ (6.7m) supplied standard for the DIN-rail Controller Module (Safety Light Curtain Model DR)

• External Alphanumeric Diagnostic & Status Message Display

• Infrared Light Source: Solid state light emitting diodes

• Beam Spacing: 1/2” (13mm) or 1” (25mm)

• Minimum Object Sensitivity:

1/2” (13mm) beam spacing is .55” (14mm)

1” (25mm) beam spacing is 1.18” (30mm)

• Response Time: < 30 milliseconds (all sizes)

• Scanning Frequency: 5.9 Khz

• Temperature Range: 32o to 120o F (0o -51o C)

• Shock tested to withstand high vibration applications per UL991

• Self-Checking every 20 milliseconds

• Scanning Distance: All units are supplied standard with a 20’ (6.1m) scanning capability. Extended range units are available,

consult your representative or the factory. Scanning distances

must be specified—75’ (22.8m) maximum.

• Complete Guarding System Supplied: Transmitter and receiver pylons, controller, mounting brackets, connectors and cables, installation and operation manual.

• CSA Approved, UL Listed, and CE Certified

• Two-Year Warranty on the Safety Light Curtain Model DR

• Patented #5,243,183

• Safety Category 4 (EN 954-1 and IEC 61496 Part 1 and Part 2 or EN 61496)

• SIL 3 (EN 61508)

• Performance Level PL e (ISO 13849-1)

• DeviceNetTM Fieldbus Network Compatible (optional)

• Input Power: 24VDC +/- 20%

• Power Consumption: 7 watts maximum

• Output Circuit: Two captive contact self-checking safety relays

• Relay Contact Rating: Rated at 8 AMPS @ 250VAC resistive | Rated at 8 AMPS @ 120VAC resistive

• Auxiliary Output Contact: 5AMP @250VAC resistive

• Input Fuse: 1 AMP FAST BLOW (pico size)

• Fault Output Relay: 5AMP @250VAC resistive

• DIN-rail Controller Indicators

External:

CLEAR/OK Green LED

BLOCK/FAULT Red LED

BLANKING ACTIVE Yellow LED

BLOCKED Red LED

Internal:

+ 5V Yellow LED’s (2)

Relays Green LED’s (4)

+ 12V Red LED (1)

– 5V Green LED (1)

• Emergency Stop Input Built-In

• Diagnostic Message Display: English or Spanish available. Customized languages are also available, consult factory.

• Push Button Reset with Memory

• Enclosure: Gray polycarbonate with clear cover. Provides IP40, UL94V-1

• Enclosure Dimensions: 5.87” (149mm) length x 4.33” (110mm) depth x 2.95” (75mm) height

• Enclosure Mounting: 35mm DIN-rail mountable or Mounting screws on corners of enclosure requiring two combo-head screws (3.5 x 0.6mm x 14mm or #6 x .5)

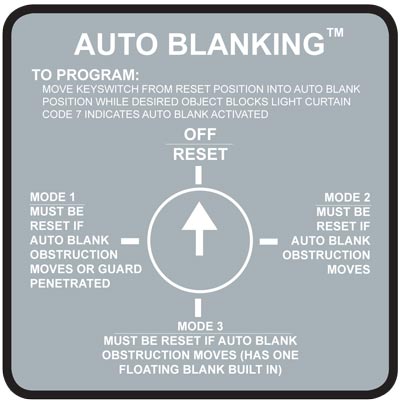

Auto-Blanking – (AB) Option

Auto-Blanking – (AB) Option

The advanced “Auto Blank” option is unique because it will automatically blank out only the required number of beams needed to accept an obstruction such as a conveyor, bracket, or fixture. The unit is easily programmed by a supervisory controlled four-position keyed selector switch located on the front panel of the MicroGuard Controller (shown left). The “Auto Blank” method of blanking is much safer than DIP switch or master/slave blanking systems because only the areas of the obstruction will be blanked. This feature prohibits unsafe oversizing of the blanked area commonly found throughout the industry on manually blanked systems. “Auto Blank” also eliminates the need to count beams and to locate where and what beams are to be shut off to obtain the correct beam elevation to accept an obstruction. This information is displayed on the message display of the controller. “Auto Blank” will also watch the obstruction and, if it moves or is removed, will go into a “machine stop mode” to prevent further machine operation. This is an additional safety feature not available on manually blanked units. These features truly enhance production while providing the ultimate in safety.

When the key switch is turned to the “Auto Blank” function, the “External Diagnostic Message Display” will show the number of blocked beams and where the obstruction is in the light curtain, then verify that the obstruction is being monitored. This is required information for the depth penetration factor and for proper installation of any safety light curtain.

The versatile “Auto Blank” (AB) blanking series includes:

Constant scan light curtain

One beam floating blank built-in plus “Auto Blank” capability

Two “Auto Blank” modes – up to 4” blanked out (larger sizes available upon request) but need not be sequential

A. One “Auto Blank” mode with keyed reset when guarded zone is penetrated

B. One “Auto Blank” mode with automatic reset when guarded zone is penetrated

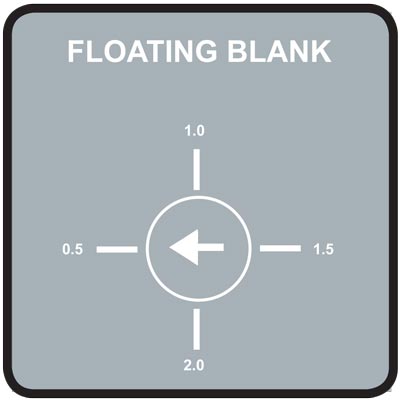

Floating Blank – (8K) Option

Floating Blank – (8K) Option

The “Floating Blank” option provides the flexibility necessary to effectively guard all types of equipment that require multiple floating beams. This is quite common in the fabricating industry where the work piece moves.

The “Floating Blank” permits work pieces to be formed vertically or horizontally through the guarded area without shutting down the machine. Entry into the protected area by the operator or passerby will prevent the start or, if the machine is in motion, will provide a signal to stop the machine.

The “Floating Blank” is controlled by a keyed selector switch that will allow a work opening of 2” (51mm) based on 1/2” (13mm) increments (shown left). This information is displayed on the message display of the controller. Blanking adjustments required when die heights change are not necessary. The “Floating Blank” light curtain automatically adjusts to the various feed positions providing production with protection.

The “Floating Blank” (8K) Option includes:

1/2” (13mm) – Constant scan light curtain

1” (25mm) – One floating beam

1-1/2” (38mm) – Two floating beams

2” (51mm) – Three floating beams

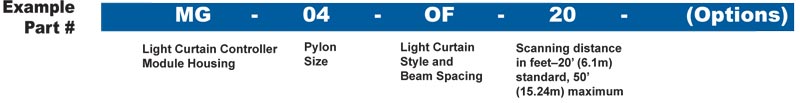

Replace “MG” with a “DR” (below) when ordering the Safety Light Curtain Model DR

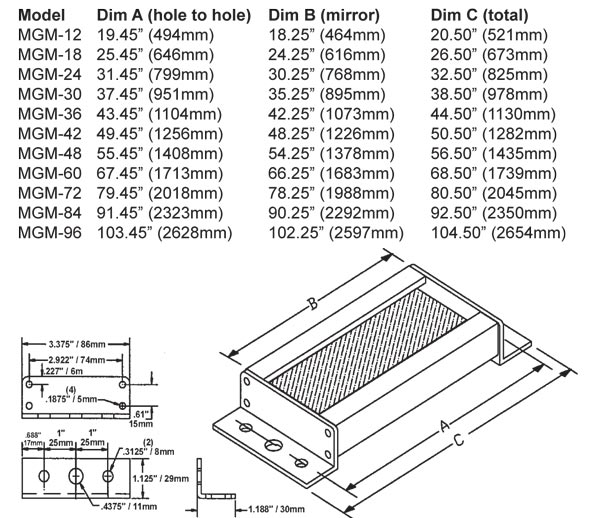

Cornering Mirrors

Through the use of cornering mirrors, multiple sides or work envelopes can be guarded which enhance safety and reduce downtime related to mechanical and electrical interlock systems. Include a 15% reflectivity loss per mirror when calculating the total scanning distance of the light curtain.

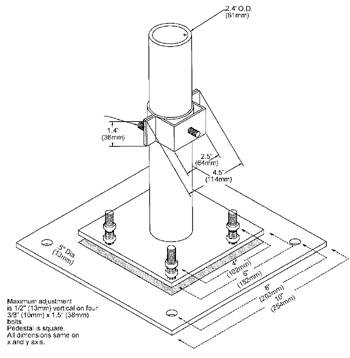

Pedestal Dimensions

The heavy duty, all welded steel pedestal floor mounts can be used for mounting either light curtain pylons or cornering mirrors. Sliding mounts on the pedestal are of universal design and are supplied standard. Unique floating base on pedestal is designed to compensate for uneven floors.

The heavy duty, all welded steel pedestal floor mounts can be used for mounting either light curtain pylons or cornering mirrors. Sliding mounts on the pedestal are of universal design and are supplied standard. Unique floating base on pedestal is designed to compensate for uneven floors.

NOTE: Pedestals must be bolted to the floor, they must not be movable (ANSI B11.19-2010).

1. Sliding mounts supplied

2. Standard height is 72” (1829mm) – Model #8000

Optional 96” (2438mm) – Model #8096

3. Painted OSHA yellow

4. Pedestal is 12 gauge steel

Base Plate is 1/4” (6.35mm) steel plate

Ordering Procedure

Specify Pedestal Model Number and Quantity

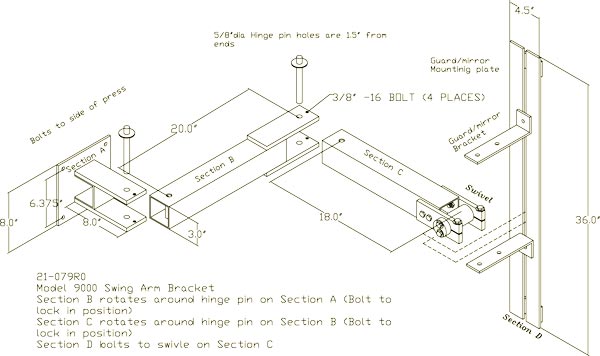

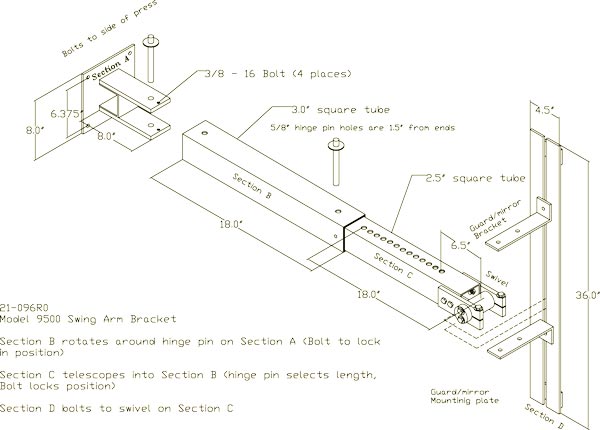

Model 9000 and 9500 Mounting Brackets

Excellent method of mounting the light guard for press brakes or when the light guard is to be moved for die setups or machine maintenance. Model 9000 consists of three 180-pivot points along with light guard diagonal movement capability for virtually unlimited light guard positioning. Two-inch square tubing 3/16” thick painted OSHA yellow which mounts directly onto the machine housing and makes for a heavy duty yet versatile mounting bracket. Model 9500 consists of two 180-pivot points and one adjustable length arm.

Model 9000

Model 9500

Part # 11-183: Two piece adjustable mounting bracket for pedestals (with one mounting stud 5/16”-18 stud). Stainless Steel (for Mirror and Guard pylon) (Two required per pedestal) Part # 11-183: Two piece adjustable mounting bracket for pedestals (with one mounting stud 5/16”-18 stud). Stainless Steel (for Mirror and Guard pylon) (Two required per pedestal) |

Part # 11-184: Two piece adjustable mounting bracket for pedestals (with one mounting stud 5/16”-18 studs 90 degrees apart). Stainless Steel (for Guard at one corner) (Two required per pedestal) Part # 11-184: Two piece adjustable mounting bracket for pedestals (with one mounting stud 5/16”-18 studs 90 degrees apart). Stainless Steel (for Guard at one corner) (Two required per pedestal) |

Part # 11-199: Two piece adjustable mounting bracket for pedestals (with two mounting studs 5/16”-18 studs 180 degrees apart). Stainless Steel (for multiple Guards mounted side by side) (Two required per pedestal) Part # 11-199: Two piece adjustable mounting bracket for pedestals (with two mounting studs 5/16”-18 studs 180 degrees apart). Stainless Steel (for multiple Guards mounted side by side) (Two required per pedestal) |

Polycarbonate Tube: Optional Polycarbonate tube which will encase the pylons for high impact protection. Polycarbonate Tube: Optional Polycarbonate tube which will encase the pylons for high impact protection. |

Replace MG with DR (above) with ordering the Safety Light Curtain Model DR

Safety Light Curtain Model DR Controller Module Housing

DR – 35mm DIN-rail Mountable Controller Module (24VDC Input Power Only)

Pylon Sizes (Protected Area)

1/2” (13mm) Beam Spacing: 04,08,12,16,20,24,28,32,36,40,44,48,52,56,60,64 68,72,76,80,84,88,92,96,100,104,108,112,116,120

1” (25mm) Beam Spacing: 04,08,12,16,20,24,28,32,36,40,44,48,52,56,60,64,68,72,76,80,84,88,92,96,100,104,108,112,116,120

4” (102mm) Beam Spacing: 20,28,36,44,52,60,68,76,84,92,100,108,116

Customized Blanking Available (consult factory)

Safety Light Curtain Model DR Style and Beam Spacing

1/2” (13mm) Spacing of Beams

OF – Constant scan – no blanking.

1F – 1 beam floating blank built-in.

8K – Up to 3 beam floating blank adjustable by the use of a keyswitch removable in all positions. Capable of constant scan or one, two, or three floating beams.

AB – Includes constant scan light curtain, one beam floating blank, and two auto blank modes.

CE – No blanking, 24VDC input power, 2° angle of divergence, and CE certified (designed to conform to the

European Market and worldwide IEC 61496 Parts 1 & 2 Standards).

1” ( 25mm) Spacing of Beams

OF1 – Constant scan – no blanking.

1F1 – 1 beam floating blank built-in.

8K1 – Up to 3 beam floating blank adjustable by the use of a keyswitch removable in all positions. Capable of constant scan or one, two, or three floating beams.

AB1 – Includes constant scan light curtain, one beam floating blank, and two auto blank modes.

CE1 – No blanking, 24VDC input power, 2° angle of divergence, and CE certified (designed to conform to the

European Market and worldwide IEC 61496 Parts 1 & 2 Standards).

4” ( 102mm) Spacing of Beams (no blanking options available, constant scan only)

OF4 – For perimeter guarding, body detection. 4.25” (108mm) object sensitivity. 4” (102mm) active area followed by a 4” (102mm) gap.

Options (Add underlined suffix to part number)

SMB – Swivel Mounting Brackets for Pylons: Replaces the fixed mounting brackets normally supplied. Provides a 360o rotation of pylons.

MO – Guarding Mute-Out: Mutes out the light curtain during the non-hazardous portion of the machine cycle.

32-108 – High Load Safety Relay – 110 VAC – 20 AMP high load safety relay incorporates a 110 VAC coil with 3 NO (held closed) and 1 NC contact. Each light curtain requires two relays. Dimensions: (45mm width x 91mm length x 85mm height)

32-109 – High Load Safety Relay – 24vdc – 20 AMP high load safety relay incorporates a 24vdc coil with 3 NO (held closed) and 1 NC contact. Each light

curtain requires two relays and EDM feature. Dimensions: (45mm width x 91mm length x 115mm height)

DN – DeviceNetTM: Fieldbus network compatible.

Extended Range Units: 21’ (6.4m) to 75’ (24.8m) scanning distances (specify desired scanning distance).

RSD – DIN-rail Remote Status Display (RSD): Remote mounting plate providing a single location to mount the following on existing panel door: light curtain scrolling diagnostic message display, blanking option keyswitch (if applicable), and status indicator lights (all styles).

CI – Cincinnati Interface: Requires the MicroGuard to issue a stop command every machine cycle (built-in standard on the Metal Box Controller Module).

AO – Analog Output for Non-Safety Applications: -10VDC to +10VDC or 0VDC to +10VDC.

Extra Pylon Protection (Optional)

PT – Polycarbonate tube which will encase the pylons for high impact protection.