In industrial environments, ensuring the safety of personnel while maintaining operational efficiency is paramount. Two prevalent safety devices employed to protect workers from hazardous machinery are safety mats and safety light curtains. Both serve as presence-sensing devices, but their applications, functionalities, and suitability vary. This comprehensive guide delves into the intricacies of safety mats and safety light curtains, exploring their functions, purposes, applicable standards, industry uses, and factors to consider when selecting the appropriate machine guarding solution for your specific application.

Understanding Safety Mats

What Are Safety Mats?

Safety mats are pressure-sensitive devices designed to detect the presence of personnel or objects on their surface. When an individual steps onto the mat, it sends a signal to the machine control system to stop or prevent hazardous operations, thereby safeguarding the person from potential harm.

How Do Safety Mats Work?

Safety mats consist of two conductive plates separated by a non-conductive spacer. When pressure is applied—such as when a person steps on the mat—the conductive plates make contact, completing an electrical circuit. This action triggers a safety relay, which then sends a stop signal to the associated machinery. The mats are typically connected to a safety controller that monitors their status and ensures proper functionality.

Purpose and Function

The primary purpose of safety mats is to provide a protective zone around hazardous machinery. By detecting the presence of personnel within a designated area, safety mats ensure that machines operate only when the area is clear, thereby preventing accidental injuries. They are particularly useful in environments where operators need regular access to machinery, as the mats allow for seamless integration of safety measures without hindering workflow.

Applicable Standards for Safety Mats

Safety mats must adhere to specific international safety standards to ensure their effectiveness and reliability. Key standards include:

- ISO 13856-1: Safety of machinery—Pressure-sensitive protective devices—Part 1: General principles for the design and testing of pressure-sensitive mats and pressure-sensitive floors.

- IEC 60947-5-1: Low-voltage switchgear and controlgear—Part 5-1: Control circuit devices and switching elements—Electromechanical control circuit devices.

Compliance with these standards ensures that safety mats are designed, tested, and maintained to provide optimal protection in industrial settings.

Industries Utilizing Safety Mats

Safety mats are employed across various industries to enhance workplace safety. Notable sectors include:

- Manufacturing: Protecting operators working with assembly lines, presses, and cutting equipment.

- Automotive: Ensuring safety in areas where workers interact with robotic systems and conveyors.

- Food Processing: Safeguarding personnel in environments with frequent washdowns, as mats can be designed to withstand such conditions.

- Pharmaceuticals: Providing safety measures in cleanroom settings where contamination control is crucial.

Factors to Consider When Choosing Safety Mats

When determining if safety mats are the appropriate solution for your application, consider the following factors:

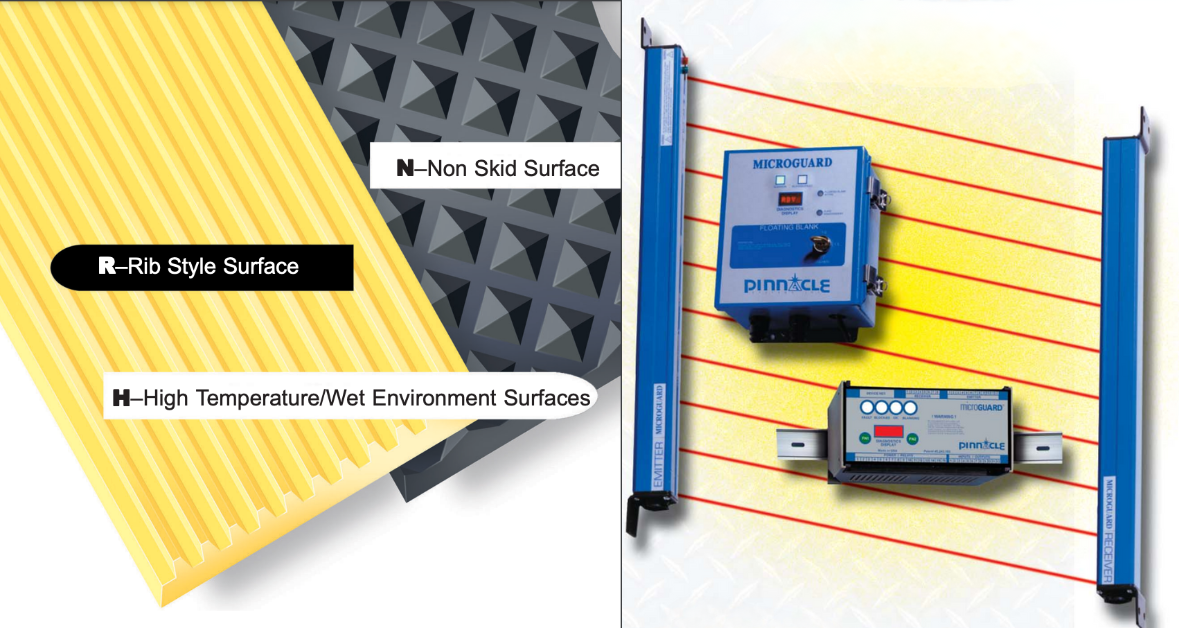

- Environmental Conditions: Assess whether the mats will be exposed to chemicals, moisture, or extreme temperatures, and choose mats designed to withstand these conditions.

- Traffic Volume: High foot or equipment traffic may lead to increased wear; ensure the selected mats are durable and suitable for such use.

- Maintenance Requirements: Regular inspection and cleaning are necessary to maintain functionality; consider the ease of maintenance in your selection.

- Integration with Existing Systems: Ensure compatibility with current machinery control systems for seamless operation.

- Cost Considerations: While safety mats may have a lower initial cost compared to other safety devices, factor in potential maintenance expenses over time.

Understanding Safety Light Curtains

What Are Safety Light Curtains?

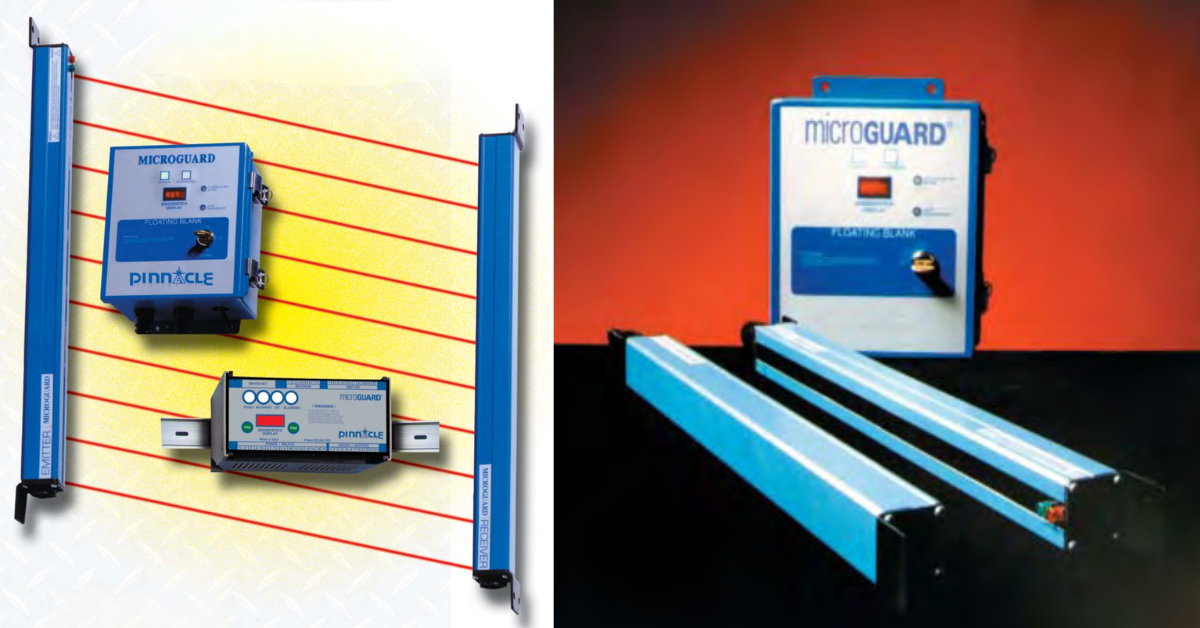

Safety light curtains are optoelectronic devices that create an invisible infrared light barrier around hazardous areas of machinery. When an object or person interrupts this light beam, the system sends a stop signal to the machine, preventing potential injuries.

How Do Safety Light Curtains Work?

A safety light curtain system comprises a transmitter and a receiver. The transmitter emits synchronized infrared light beams to the receiver, forming a protective screen. If any beam is interrupted, the receiver detects the absence of the signal and triggers a safety response, such as stopping the machine. Advanced systems can differentiate between objects of various sizes, allowing for customizable safety responses.

Purpose and Function of Safety Light Curtains

The primary function of safety light curtains is to provide non-contact detection of personnel entering hazardous zones. This allows for immediate cessation of machine operations upon detection, thereby preventing accidents. Safety light curtains are especially beneficial in applications requiring frequent access to machinery, as they do not impede movement and allow for ergonomic workflow.

Applicable Standards for Safety Light Curtains

Safety light curtains must comply with stringent safety standards to ensure their reliability and effectiveness. Relevant standards include:

- IEC 61496-1/-2: Safety of machinery—Electro-sensitive protective equipment—Part 1: General requirements and tests; Part 2: Particular requirements for equipment using active opto-electronic protective devices.

- ANSI B11.19: Performance criteria for safeguarding, which outlines the requirements for the design, construction, installation, operation, and maintenance of safeguarding devices, including safety light curtains.

Adherence to these standards ensures that safety light curtains provide reliable protection and are suitable for industrial applications.

Industries Utilizing Safety Light Curtains

Safety light curtains are widely used across various industries to enhance safety measures. Key sectors include:

- Automotive Manufacturing: Protecting workers in areas with robotic arms and automated assembly lines.

- Packaging: Ensuring operator safety around machinery involved in high-speed packaging processes.

- Metalworking: Safeguarding personnel operating

Safety Mats vs. Safety Light Curtains: A Detailed Comparison

Choosing between safety mats and safety light curtains depends on several factors, including application requirements, cost, installation complexity, maintenance, and compliance with safety regulations. Below is a side-by-side comparison to help determine the best solution for your facility.

| Feature | Safety Mats | Safety Light Curtains |

| Primary Function | Detects physical presence on the mat’s surface, triggering a machine stop. | Uses infrared beams to detect movement or entry into hazardous areas, stopping machinery. |

| Best Use Cases | Suitable for areas where operators frequently stand near hazardous equipment or need defined safety zones. | Ideal for applications requiring frequent access, such as robotic cells or conveyor systems. |

| Common Industries | Manufacturing, automotive, food processing, pharmaceuticals, material handling. | Automotive, metalworking, packaging, automated assembly, material handling. |

| Physical Space Requirements | Requires floor space and must be placed directly in the work zone. | Requires vertical mounting but does not take up floor space. |

| Obstruction Considerations | May be obstructed by equipment, carts, or debris. | Does not obstruct workflow, allowing easy access for operators. |

| Response Time | Instantaneous when pressure is applied. | Instantaneous when a beam is interrupted. |

| Installation Complexity | Easier to install; can be placed on the floor and connected to safety controllers. | Requires precise alignment of transmitter and receiver; may need adjustments for optimal functionality. |

| Durability & Environmental Resistance | Designed for industrial environments; can withstand heavy foot traffic and machinery weight. | Can be affected by dust, smoke, and reflective surfaces, requiring additional calibration in challenging environments. |

| Maintenance Requirements | Requires periodic inspection for wear and tear, as mats can degrade over time. | Lower maintenance, but sensors must be cleaned regularly to avoid false detections. |

| Cost Considerations | Lower initial cost but may require more frequent replacements due to physical wear. | Higher initial cost but generally longer-lasting with fewer maintenance costs. |

| Regulatory Compliance | ISO 13856-1, IEC 60947-5-1, OSHA 29 CFR 1910.212. | IEC 61496-1/-2, ANSI B11.19, OSHA 29 CFR 1910.212. |

Which One Should You Choose?

- Choose Safety Mats If:

-

-

- You need defined safety zones around hazardous machinery.

- Workers frequently stand in designated areas while operating machines.

- Your facility has a dirty or dusty environment, which could interfere with light curtain sensors.

- Cost is a major factor, and you prefer a lower upfront investment despite possible maintenance costs.

-

- Choose Safety Light Curtains If:

-

- Your application requires unobstructed access to machines or conveyor systems.

- Operators frequently move in and out of hazardous zones.

- You need a non-contact safety solution for ergonomic efficiency.

- You want long-term durability with minimal maintenance.

By carefully assessing your facility’s needs, environmental conditions, and budget, you can determine whether safety mats or safety light curtains offer the best protection for your workforce.

Making the Right Choice for Machine Guarding

Both safety mats and safety light curtains play crucial roles in machine guarding and workplace safety, but choosing the right solution depends on your specific application, environment, and safety requirements.

Final Decision: Safety Mats or Light Curtains?

The best choice depends on your facility’s unique safety needs:

- Choose Safety Mats if you need rugged, pressure-sensitive guarding that detects workers standing near a machine.

- Choose Safety Light Curtains if you require advanced, non-contact safety for flexible and frequent operator access.

Regardless of the option you choose, proper installation, regular maintenance, and compliance with OSHA and ANSI standards are essential for maximizing workplace safety.

If you’re looking for high-quality safety mats or light curtains, explore Pinnacle Systems’ safety products to find the best solution for your machine guarding needs.