1910.217

Mechanical power presses

(a)

General requirements.

(1)

[Reserved]

(2) [Reserved]

(3) [Reserved]

(4) Reconstruction and

modification.

It shall be the responsibility of any person

reconstructing, or modifying a mechanical power press

to do so in accordance with paragraph (b) of this

section.

(5) Excluded machines.

Press brakes, hydraulic and pneumatic power presses,

bulldozers, hot bending and hot metal presses, forging

presses and hammers, riveting machines and similar

types of fastener applicators are excluded from the

requirements of this section.

(b)

Mechanical power press guarding and

construction, general -

(1)

Hazards to personnel associated with

broken or falling machine

components.

Machine components shall be designed, secured, or

covered to minimize hazards caused by breakage, or

loosening and falling or release of mechanical energy

(i.e. broken springs).

(2) Brakes.

Friction brakes provided for stopping or holding a

slide movement shall be inherently self-engaging by

requiring power or force from an external source to

cause disengagement. Brake capacity shall be sufficient

to stop the motion of the slide quickly and capable of

holding the slide and its attachments at any point in

its travel.

(3) Machines using full revolution positive

clutches.

(i)

Machines using full revolution clutches shall

incorporate a single-stroke mechanism.

(ii) If the single-stroke mechanism is dependent

upon spring action, the spring(s) shall be of the

compression type, operating on a rod or guided

within a hole or tube, and designed to prevent

interleaving of the spring coils in event of

breakage.

(4)

Foot pedals

(treadle).

(i) The

pedal mechanism shall be protected to prevent

unintended operation from falling or moving

objects or by accidental stepping onto the

pedal.

(ii) A pad with a nonslip contact area shall be

firmly attached to the pedal.

(iii) The pedal return spring(s) shall be of the

compression type, operating on a rod or guided

within a hole or tube, or designed to prevent

interleaving of spring coils in event of

breakage.

(iv) If pedal counterweights are provided, the path

of the travel of the weight shall be

enclosed.

(5)

Hand operated

levers.

(i)

Hand-lever-operated power presses shall be

equipped with a spring latch on the operating

lever to prevent premature or accidental

tripping.

(ii) The operating levers on hand-tripped presses

having more than one operating station shall be

interlocked to prevent the tripping of the press

except by the “concurrent” use of all

levers.

(6)

Two-hand

trip.

(i) A

two-hand trip shall have the individual

operator’s hand controls protected against

unintentional operation and have the

individual operator’s hand controls arranged

by design and construction and/or separation

to require the use of both hands to trip the

press and use a control arrangement requiring

concurrent operation of the individual

operator’s hand controls.

(ii) Two-hand trip systems on full revolution

clutch machines shall incorporate an antirepeat

feature.

(iii) If two-hand trip systems are used on multiple

operator presses, each operator shall have a

separate set of controls.

(7)

Machines using part revolution

clutches.

(i) The

clutch shall release and the brake shall be

applied when the external clutch engaging

means is removed, deactivated, or

deenergized.

(ii) A red color stop control shall be provided

with the clutch/brake control system. Momentary

operation of the stop control shall immediately

deactivate the clutch and apply the brake. The stop

control shall override any other control, and

reactuation of the clutch shall require use of the

operating (tripping) means which has been

selected.

(iii) A means of selecting Off, “Inch,” Single

Stroke, and Continuous (when the continuous

function is furnished) shall be supplied with the

clutch/brake control to select type of operation of

the press. Fixing of selection shall be by means

capable of supervision by the employer.

(iv) The “Inch” operating means shall be designed

to prevent exposure of the workers hands within the

point of operation by:

(a) Requiring the concurrent use of both hands to

actuate the clutch, or

(b) Being a single control protected against

accidental actuation and so located that the worker

cannot reach into the point of operation while

operating the single control.

(v) Two-hand controls for single stroke shall

conform to the following requirements:

(a)

Each hand control shall be protected

against unintended operation and arranged

by design, construction, and/or

separation so that the concurrent use of

both hands is required to trip the

press.

(b) The control system shall be designed to

permit an adjustment which will require

concurrent pressure from both hands during the

die closing portion of the stroke.

(c) The control system shall incorporate an

antirepeat feature.

(d) The control systems shall be designed to

require release of all operators’ hand controls

before an interrupted stroke can be resumed.

This requirement pertains only to those

single-stroke, two-hand controls manufactured

and installed on or after August 31,

1971.

(vi)

[Reserved]

(vii) Controls for more than one operating station

shall be designed to be activated and deactivated

in complete sets of two operator’s hand controls

per operating station by means capable of being

supervised by the employer. The clutch/brake

control system shall be designed and constructed to

prevent actuation of the clutch if all operating

stations are bypassed.

(viii) Those clutch/brake control systems which

contain both single and continuous functions shall

be designed so that completion of continuous

circuits may be supervised by the employer. The

initiation of continuous run shall require a prior

action or decision by the operator in addition to

the selection of Continuous on the stroking

selector, before actuation of the operating means

will result in continuous stroking.

(ix) If foot control is provided, the selection

method between hand and foot control shall be

separate from the stroking selector and shall be

designed so that the selection may be supervised by

the employer.

(x) Foot operated tripping controls, if used, shall

be protected so as to prevent operation from

falling or moving objects, or from unintended

operation by accidental stepping onto the foot

control.

(xi) The control of air-clutch machines shall be

designed to prevent a significant increase in the

normal stopping time due to a failure within the

operating value mechanism, and to inhibit further

operation if such failure does occur. This

requirement shall apply only to those clutch/brake

air-valve controls manufactured and installed on or

after August 31, 1971, but shall not apply to

machines intended only for continuous, automatic

feeding applications.

(xii) The clutch/brake control shall incorporate an

automatic means to prevent initiation or continued

activation of the Single Stroke or Continuous

functions unless the press drive motor is energized

and in the forward direction.

(xiii) The clutch/brake control shall automatically

deactivate in event of failure of the power or

pressure supply for the clutch engaging means.

Reactivation of the clutch shall require

restoration of normal supply and the use of the

tripping mechanism(s).

(xiv) The clutch/brake control shall automatically

deactivate in event of failure of the

counterbalance(s) air supply. Reactivation of the

clutch shall require restoration of normal air

supply and use of the tripping mechanism(s).

(xv) Selection of bar operation shall be by means

capable of being supervised by the employer. A

separate pushbutton shall be employed to activate

the clutch, and the clutch shall be activated only

if the driver motor is deenergized.

(8)

Electrical.

(i) A

main power disconnect switch capable of being

locked only in the Off position shall be

provided with every power press control

system.

(ii) The motor start button shall be protected

against accidental operation.

(iii) All mechanical power press controls shall

incorporate a type of drive motor starter that will

disconnect the drive motor from the power source in

event of control voltage or power source failure,

and require operation of the motor start button to

restart the motor when voltage conditions are

restored to normal.

(iv) All a.c. control circuits and solenoid value

coils shall be powered by not more than a nominal

120-volt a.c. supply obtained from a transformer

with an isolated secondary. Higher voltages that

may be necessary for

operation of machine or control mechanisms shall be

isolated from any control mechanism handled by the

operator, but motor starters with integral

Start-Stop buttons may utilize line voltage

control. All d.c. control circuits shall be powered

by not more than a nominal 240-volt d.c. supply

isolated from any higher voltages.

(v) All clutch/brake control electrical circuits

shall be protected against the possibility of an

accidental ground in the control circuit causing

false operation of the press.

(vi) Electrical clutch/brake control circuits shall

incorporate features to minimize the possibility of

an unintended stroke in the event of the failure of

a control component to function properly, including

relays, limit switches, and static output

circuits.

(9)

Slide counterbalance

systems.

(i)

Spring counterbalance systems when used shall

incorporate means to retain system parts in

event of breakage.

(ii) Spring counterbalances when used shall have

the capability to hold the slide and its

attachments at midstroke, without brake

applied.

(iii) Air counterbalance cylinders shall

incorporate means to retain the piston and rod in

case of breakage or loosening.

(iv) Air counterbalance cylinders shall have

adequate capability to hold the slide and its

attachments at any point in stroke, without brake

applied.

(v) Air counterbalance cylinders shall incorporate

means to prevent failure of capability (sudden loss

of pressure) in event of air supply

failure.

(10)

Air controlling

equipment.

Air controlling equipment shall be protected against

foreign material and water entering the pneumatic

system of the press. A means of air lubrication shall

be provided when needed.

(11)

Hydraulic

equipment.

The maximum anticipated working pressures in any

hydraulic system on a mechanical power press shall not

exceed the safe working pressure rating of any

component used in that system.

(12)

Pressure vessels.

All pressure vessels used in conjunction with power

presses shall conform to the American Society of

Mechanical Engineers Code for Pressure Vessels, 1968

Edition, which is incorporated by reference as

specified in Sec. 1910.6.

(13)

Control

reliability.

When required by paragraph (c)(5) of this section, the

control system shall be constructed so that a failure

within the system does not prevent the normal stopping

action from being applied to the press when required,

but does prevent initiation of a successive stroke

until the failure is corrected. The failure shall be

detectable by a simple test, or indicated by the

control system. This requirement does not apply to

those elements of the control system which have no

effect on the protection against point of operation

injuries.

(14)

Brake system

monitoring.

When required by paragraph (c)(5) of this section, the

brake monitor shall meet the following

requirements:

(i) Be so

constructed as to automatically prevent the

activation of a successive stroke if the

stopping time or braking distance

deteriorates to a point where the safety

distance being utilized does not meet the

requirements set forth in paragraph

(c)(3)(iii)(e) or (c)(3)(vii)(c) of this

section. The brake monitor used with the Type

B gate or movable barrier device shall be

installed in a manner to detect slide

top-stop overrun beyond the normal limit

reasonably established by the employer.

(ii) Be installed on a press such that it indicates

when the performance of the braking system has

deteriorated to the extent described in paragraph

(b)(14)(i) of this section;

and

(iii) Be

constructed and installed in a manner to

monitor brake system performance on each

stroke.

(c)

Safeguarding the point of operation

-

(1)

General

requirements.

(i) It

shall be the responsibility of the employer

to provide and insure the usage of “point of

operation guards” or properly applied and

adjusted point of operation devices on every

operation performed on a mechanical power

press. See Table O-10.

(ii) The requirement of paragraph (c)(1)(i) of this

section shall not apply when the point of operation

opening is one-fourth inch or less. See Table

O-10.

(2)

Point of operation

guards.

(i) Every

point of operation guard shall meet the

following design, construction, application,

and adjustment requirements:

(a)

It shall prevent entry of hands or

fingers into the point of operation by

reaching through, over, under or around

the guard;

(b) It shall conform to the maximum permissible

openings of Table O-10;

(c) It shall, in itself, create no pinch point

between the guard and moving machine parts;

(d) It shall utilize fasteners not readily

removable by operator, so as to minimize the

possibility of misuse or removal of essential

parts;

(e) It shall facilitate its inspection, and

(f) It shall offer maximum visibility of the

point of operation consistent with the other

requirements.

(ii) A

die enclosure guard shall be attached to the

die shoe or stripper in a fixed position.

(iii) A fixed barrier guard shall be attached

securely to the frame of the press or to the

bolster plate.

(iv) An interlocked press barrier guard shall be

attached to the press frame or bolster and shall be

interlocked with the press clutch control so that

the clutch cannot be activated unless the guard

itself, or the hinged or movable sections of the

guard are in position to conform to the

requirements of Table O-10.

(v) The hinged or movable sections of an

interlocked press barrier guard shall not be used

for manual feeding. The guard shall prevent opening

of the interlocked section and reaching into the

point of operation prior to die closure or prior to

the cessation of slide motion. See paragraph

(c)(3)(ii) of this section regarding manual feeding

through interlocked press barrier devices.

(vi) The adjustable barrier guard shall be securely

attached to the press bed, bolster plate, or die

shoe, and shall be adjusted and operated in

conformity with Table O-10 and the requirements of

this subparagraph. Adjustments shall be made only

by authorized personnel whose qualifications

include a knowledge of the provisions of Table O-10

and this subparagraph.

(vii) A point of operation enclosure which does not

meet the requirements of this subparagraph and

Table O-10 shall be used only in conjunction with

point of operation devices.

(3)

Point of operation

devices.

(i) Point

of operation devices shall protect the

operator by:

(a)

Preventing and/or stopping normal

stroking of the press if the operator’s

hands are inadvertently placed in the

point of operation; or

(b) Preventing the operator from inadvertently

reaching into the point of operation, or

withdrawing his hands if they are inadvertently

located in the point of operation, as the dies

close; or

(c) Preventing the operator from inadvertently

reaching into the point of operation at all

times; or

(d) [Reserved]

(e) Requiring application of both of the

operator’s hands to machine operating controls

and locating such controls at such a safety

distance from the point of operation that the

slide completes the downward travel or stops

before the operator can reach into the point of

operation with his hands; or

(f) Enclosing the point of operation before a

press stroke can be initiated, and maintaining

this closed condition until the motion of the

slide had ceased; or

(g) Enclosing the point of operation before a

press stroke can be initiated, so as to prevent

an operator from reaching into the point of

operation prior to die closure or prior to

cessation of slide motion during the downward

stroke.

(ii) A

gate or movable barrier device shall protect

the operator as follows:

(a) A

Type A gate or movable barrier device

shall protect the operator in the manner

specified in paragraph (c)(3)(i)(f) of

this section, and

(b) A Type B gate or movable barrier device

shall protect the operator in the manner

specified in paragraph (c)(3)(i)(g) of this

section.

(iii) A

presence sensing point of operation device

shall protect the operator as provided in

paragraph (c)(3)(i)(a) of this section, and

shall be interlocked into the control circuit

to prevent or stop slide motion if the

operator’s hand or other part of his body is

within the sensing field of the device during

the downstroke of the press slide.

(a)

The device may not be used on machines

using full revolution clutches.

(b) The device may not be used as a tripping

means to initiate slide motion.

(c) The device shall be constructed so that a

failure within the system does not prevent the

normal stopping action from being applied to

the press when required, but does prevent the

initiation of a successive stroke until the

failure is corrected. The failure shall be

indicated by the system.

(d) Muting (bypassing of the protective

function) of such device, during the upstroke

of the press slide, is permitted for the

purpose of parts ejection, circuit checking,

and feeding.

(e) The safety distance (D(s)) from the sensing

field to the point of operation shall be

greater than the distance determined by the

following formula:

D(s)

= 63 inches/second X T(s)

where:

D(s) = minimum safety distance (inches); 63

inches/second = hand speed constant;

and

T(s) = stopping time of the press measured at

approximately 90 degree position of crankshaft

rotation (seconds).

(f) Guards shall be used to protect all areas

of entry to the point of operation not

protected by the presence sensing

device.

(iv) The

pull-out device shall protect the operator as

specified in paragraph (c)(3)(i)(b) of this

section, and shall include attachments for

each of the operator’s hands.

(a)

Attachments shall be connected to and

operated only by the press slide or upper

die.

(b) Attachments shall be adjusted to prevent

the operator from reaching into the point of

operation or to withdraw the operator’s hands

from the point of operation before the dies

close.

(c) A separate pull-out device shall be

provided for each operator if more than one

operator is used on a press.

(d) Each pull-out device in use shall be

visually inspected and checked for proper

adjustment at the start of each operator shift,

following a new die set-up, and when operators

are changed. Necessary maintenance or repair or

both shall be performed and completed before

the press is operated. Records of inspections

and maintenance shall be kept in accordance

with paragraph (e) of this section.

(v) The

sweep device may not be used for point of

operation safeguarding.

(vi) A holdout or a restraint device shall protect

the operator as specified in paragraph (c)(3)(i)(c)

of this section and shall include attachments for

each of the operator’s hands. Such attachments

shall be securely anchored and adjusted in such a

way that the operator is restrained from reaching

into the point of operation. A separate set of

restraints shall be provided for each operator if

more than one operator is required on a press.

(vii) The two hand control device shall protect the

operator as specified in paragraph (c)(3)(i)(e) of

this section.

(a)

When used in press operations requiring

more than one operator, separate two hand

controls shall be provided for each

operator, and shall be designed to

require concurrent application of all

operators’ controls to activate the

slide. The removal of a hand from any

control button shall cause the slide to

stop.

(b) Each two hand control shall meet the

construction requirements of paragraph

(b)(7)(v) of this section.

(c) The safety distance (D(s)) between each two

hand control device and the point of operation

shall be greater than the distance determined

by the following formula:

D(s)

= 63 inches/second X

T(s);

where:

D(s) = minimum safety distance (inches); 63

inches/second=hand speed constant;

and

T(s) = stopping time of the press measured at

approximately 90 degree position of crankshaft

rotation (seconds).

(d)

Two hand controls shall be fixed in

position so that only a supervisor or

safety engineer is capable of relocating

the controls.

(viii)

The two hand trip device shall protect the

operator as specified in paragraph

(c)(3)(i)(e) of this section.

(a)

When used in press operations requiring

more than one operator, separate two hand

trips shall be provided for each

operator, and shall be designed to

require concurrent application of all

operators’ to activate the slide.

(b) Each two hand trip shall meet the

construction requirements of paragraph (b)(6)

of this section.

(c) The safety distance (D(m)) between the two

hand trip and the point of operation shall be

greater than the distance determined by the

following formula:

D(m)

= 63 inches/second X

T(m);

where:

D(m) = minimum safety distance (inches); 63

inches/second=hand speed constant; and

T(m) = the maximum time the press takes for the

die closure after it has been tripped

(seconds). For full revolution clutch presses

with only one engaging point T(m) is equal to

the time necessary for one and one-half

revolutions of the crankshaft.

For full revolution clutch presses with more

than one engaging point, T(m) shall be

calculated as follows:

T(m) = [1/2 + (1 divided by Number of engaging

points per revolution)]

X time necessary to complete one revolution of

the crankshaft (seconds).

(d)

Two hand trips shall be fixed in position

so that only a supervisor or safety

engineer is capable of relocating the

controls.

(4)

Hand feeding tools.

Hand feeding tools are intended for placing and

removing materials in and from the press. Hand feeding

tools are not a point of operation guard or protection

device and shall not be used in lieu of the “guards” or

devices required in this section.

(5)

Additional requirements for

safe-guarding.

Where the operator feeds or removes parts by placing

one or both hands in the point of operation, and a two

hand control, presence sensing device of Type B gate or

movable barrier (on a part revolution clutch) is used

for safeguarding:

(i) The

employer shall use a control system and a

brake monitor which comply with paragraphs

(b)(13) and (14) of this section;

(ii) The exception in paragraph (b) (7)(v)(d) of

this section for two hand controls manufactured and

installed before August 31, 1971 is not applicable

under this paragraph (c)(5);

(iii) The control of air clutch machines shall be

designed to prevent a significant increase in the

normal stopping time due to a failure within the

operating valve mechanism, and to inhibit further

operation if such failure does occur, where a part

revolution clutch is employed. The exception in

paragraph (b)(7)(xi) of this section for controls

manufactured and installed before August 31, 1971,

is not applicable under this paragraph

(c)(5).

(d)

Design, construction, setting and feeding of

dies .

(1)

General requirements. The employer

shall:

(i) Use

dies and operating methods designed to

control or eliminate hazards to operating

personnel; and

(ii) Furnish and enforce the use of hand tools for

freeing and removing stuck work or scrap pieces

from the die, so that no employee need reach into

the point of operation for such

purposes.

(2)[Reserved]

(3) Scrap handling.

The employer shall provide means for handling scrap

from roll feed or random length stock operations. Scrap

cutters used in conjunction with scrap handling systems

shall be safeguarded in accordance with paragraph (c)

of this section and with 1910.219.

(4) Guide post hazard.

The hazard created by a guide post (when it is located

in the immediate vicinity of the operator) when

separated from its bushing by more than one-fourth inch

shall be considered as a point of operation hazard and

be protected in accordance with paragraph (c) of this

section.

(5) Unitized tooling.

If unitized tooling is used, the opening between the

top of the punch holder and the face of the slide, or

striking pad, shall be safeguarded in accordance with

the requirements of paragraph (c) of this section.

(6) Tonnage, stroke, and weight

designation.

All dies shall be:

(i)

Stamped with the tonnage and stroke

requirements, or have these characteristics

recorded if these records are readily

available to the die setter;

(ii) Stamped to indicate upper die weight when

necessary for air counterbalance pressure

adjustment; and

(iii) Stamped to indicate complete die weight when

handling equipment may become

overloaded.

(7)

Die fastening.

Provision shall be made in both the upper and lower

shoes for securely mounting the die to the bolster and

slide. Where clamp caps or setscrews are used in

conjunction with punch stems, additional means of

securing the upper shoe to the slide shall be used.

(8) Die handling.

Handling equipment attach points shall be provided on

all dies requiring mechanical handling.

(9) Diesetting.

(i) The

employer shall establish a diesetting

procedure that will insure compliance with

paragraph (c) of this section.

(ii) The employer shall provide spring loaded

turnover bars, for presses designed to accept such

turnover bars.

(iii) The employer shall provide die stops or other

means to prevent losing control of the die while

setting or removing dies in presses which are

inclined.

(iv) The employer shall provide and enforce the use

of safety blocks for use whenever dies are being

adjusted or repaired in the press.

(v) The employer shall provide brushes, swabs,

lubricating rolls, and automatic or manual pressure

guns so that operators and diesetters shall not be

required to reach into the point of operation or

other hazard areas to lubricate material, punches

or dies.

(e)

Inspection, maintenance, and modification of

presses -

(1)

Inspection and maintenance

records.

(i) It

shall be the responsibility of the employer

to establish and follow a program of periodic

and regular inspections of his power presses

to ensure that all their parts, auxiliary

equipment, and safeguards are in a safe

operating condition and adjustment. The

employer shall maintain a certification

record of inspections which includes the date

of inspection, the signature of the person

who performed the inspection and the serial

number, or other identifier, of the power

press that was inspected.

(ii) Each press shall be inspected and tested no

less than weekly to determine the condition of the

clutch/brake mechanism, antirepeat feature and

single stroke mechanism. Necessary maintenance or

repair or both shall be performed and completed

before the press is operated. These requirements do

not apply to those presses which comply with

paragraphs (b) (13) and (14) of this section. The

employer shall maintain a certification record of

inspections, tests and maintenance work which

includes the date of the inspection, test or

maintenance; the signature of the person who

performed the inspection, test, or maintenance; and

the serial number or other identifier of the press

that was inspected, tested or

maintained.

(2)

Modification.

It shall be the responsibility of any person modifying

a power press to furnish instructions with the

modification to establish new or changed guidelines for

use and care of the power press so modified.

(3) Training of maintenance

personnel.

It shall be the responsibility of the employer to

insure the original and continuing competence of

personnel caring for, inspecting, and maintaining power

presses.

(f)

Operation of power

presses.

(1)

[Reserved]

(2) Instruction to

operators.

The employer shall train and instruct the operator in

the safe method of work before starting work on any

operation covered by this section. The employer shall

insure by adequate supervision that correct operating

procedures are being followed.

(3) Work area.

The employer shall provide clearance between machines

so that movement of one operator will not interfere

with the work of another. Ample room for cleaning

machines, handling material, work pieces, and scrap

shall also be provided. All surrounding floors shall be

kept in good condition and free from obstructions,

grease, oil, and water.

(4) Overloading.

The employer shall operate his presses within the

tonnage and attachment weight ratings specified by the

manufacturer.

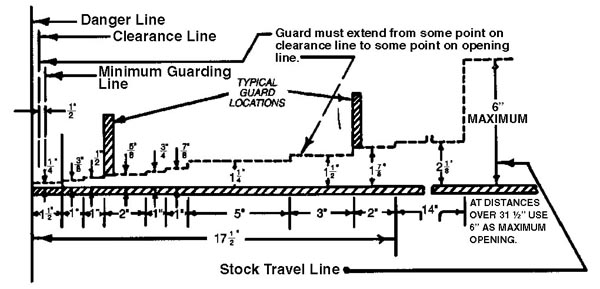

Explanation

of above diagram:

This diagram shows the accepted safe openings between

the bottom edge of a guard and feed table at various

distances from the danger line (point of operation).

The clearance line marks the distance required to

prevent contact between guard and moving parts. The

minimum guarding line is the distance between the

infeed side of the guard and the danger line which is

one-half inch from the danger line. The various

openings are such that for average size hands an

operator’s fingers won’t reach the point of operation.

After installation of point of operation guards and

before a job is released for operation a check should

be made to verify that the guard will prevent the

operator’s hands from reaching the point of

operation.

| This

table shows the distances that guards

shall be positioned from the danger

line in accordance wtih the required

openings. |

Table

O-10

[In inches]

|

| Distance

of opening from point of operation

hazard |

Maximum

width of opening

|

1/2 to

1

1/2................................1/4

1 1/2 to 2

1/2.............................3/8

2 1/2 to 3

1/2.............................1/2

3 1/2 to 5

1/2.............................5/8

5 1/2 to 6

1/2.............................3/4

6 1/2 to 7

1/2.............................7/8

7 1/2 to 12 1/2........................ 1

1/4

12 1/2 to 15 1/2...................... 1

1/2

15 1/2 to 17 1/2...................... 1

7/8

17 1/2 to 31 1/2.......................2

1/8 |

(g)

Reports of injuries to employees operating

mechanical power presses.

(1) The

employer shall, within 30 days of the occurrence,

report to either the Director of the Directorate

of Safety Standards Programs, OSHA, U.S.

Department of Labor, Washington, D.C. 20210, or

the State agency administering a plan approved by

the Assistant Secretary of Labor for Occupational

Safety and Health, all point of operation

injuries to operators or other employees. The

following information shall be included in the

report:

(i)

Employer’s name, address and location of the

workplace (establishment).

(ii) Employee’s name, injury sustained, and the

task being performed (operation, set-up,

maintenance, or other).

(iii) Type of clutch used on the press (full

revolution, part revolution, or direct drive).

(iv) Type of safeguard(s) being used (two hand

control, two hand trip, pull-outs, sweeps, or

other). If the safeguard is not described in this

section, give a complete

description.

(v) Cause

of the accident (repeat of press, safeguard

failure, removing stuck part or scrap, no

safeguard provided, no safeguard in use, or

other).

(vi) Type of feeding (manual with hands in dies or

with hands out of dies, semiautomatic, automatic,

or other).

(vii) Means used to actuate press stroke (foot

trip, foot control, hand trip, hand control, or

other).

(viii) Number of operators required for the

operation and the number of operators provided with

controls and safeguards.

(h)

Presence sensing device initiation

(PSDI).

(1)

General

(i) The

requirements of paragraph (h) shall apply to

all part revolution mechanical power presses

used in the PSDI mode of operation.

(ii) The relevant requirements of paragraphs (a)

through (g) of this section also shall apply to all

presses used in the PSDI mode of operation whether

or not cross referenced in this paragraph (h). Such

cross-referencing of specific requirements from

paragraphs (a) through (g) of this section is

intended only to enhance convenience and

understanding in relating to the new provisions to

the existing standard, and is not to be construed

as limiting the applicability of other provisions

in paragraphs (a) through (g) of this section.

(iii) Full revolution mechanical power presses

shall not be used in the PSDI mode of

operation.

(iv) Mechanical power presses with a configuration

which would allow a person to enter, pass through,

and become clear of the sensing field into the

hazardous portion of the press shall not be used in

the PSDI mode of operation.

(v) The PSDI mode of operation shall be used only

for normal production operations. Die-setting and

maintenance procedures shall comply with paragraphs

(a) through (g) of this section, and shall not be

done in the PSDI mode.

(2)

Brake and clutch

requirements.

(i)

Presses with flexible steel band brakes or

with mechanical linkage actuated brakes or

clutches shall not be used in the PSDI

mode.

(ii) Brake systems on presses used in the PSDI mode

shall have sufficient torque so that each average

value of stopping times (Ts) for stops initiated at

approximately 45 degrees, 60 degrees, and 90

degrees, respectively, of crankshaft angular

position, shall not be more than 125 percent of the

average value of the stopping time at the top

crankshaft position. Compliance with this

requirement shall be determined by using the

heaviest upper die to be used on the press, and

operating at the fastest press speed if there is

speed selection.

(iii) Where brake engagement and clutch release is

effected by spring action, such springs(s) shall

operate in compression on a rod or within a hole or

tube, and shall be of non-interleaving

design.

(3)

Pneumatic

systems.

(i) Air

valve and air pressure

supply/control.

(A)

The requirements of paragraphs

(b)(7)(xiii), (b)(7)(xiv), (b)(10),

(b)(12) and (c)(5)(iii) of this section

apply to the pneumatic systems of

machines used in the PSDI mode.

(B) The air supply for pneumatic clutch/brake

control valves shall incorporate a filter, an

air regulator, and, when necessary for proper

operation, a lubricator.

(C) The air pressure supply for clutch/brake

valves on machines used in the PSDI mode shall

be regulated to pressures less than or equal to

the air pressure used when making the stop time

measurements required by paragraph (h)(2)(ii)

of this section.

(ii) Air

counterbalance systems.

(A)

Where presses that have slide

counterbalance systems are used in the

PSDI mode, the counterbalance system

shall also meet the requirements of

paragraph (b)(9) of this section.

(B) Counterbalances shall be adjusted in

accordance with the press manufacturer’s

recommendations to assure correct

counterbalancing of the slide attachment (upper

die) weight for all operations performed on

presses used in the PSDI mode. The adjustments

shall be made before performing the stopping

time measurements required by paragraphs

(h)(2)(ii), (h)(5)(iii), and (h)(9)(v) of this

section.

(4)

Flywheels and

bearings.

Presses whose designs incorporate flywheels running on

journals on the crankshaft or back shaft, or bull gears

running on journals mounted on the crankshaft, shall be

inspected, lubricated, and maintained as provided in

paragraph (h)(10) of this section to reduce the

possibility of unintended and uncontrolled press

strokes caused by bearing seizure.

(5)

Brake

monitoring.

(i)

Presses operated in the PSDI mode shall be

equipped with a brake monitor that meets the

requirements of paragraphs (b)(13) and

(b)(14) of this section. In addition, the

brake monitor shall be adjusted during

installation certification to prevent

successive stroking of the press if increases

in stopping time cause an increase in the

safety distance above that required by

paragraph (h)(9)(v) of this section.

(ii) Once the PSDI safety system has been

certified/validated, adjustment of the brake

monitor shall not be done without prior approval of

the validation organization for both the brake

monitor adjustment and the corresponding adjustment

of the safety distance. The validation organization

shall in its installation validation, state that in

what circumstances, if any, the employer has

advance approval for adjustment, when prior oral

approval is appropriate and when prior approval

must be in writing. The adjustment shall be done

under the supervision of an authorized person whose

qualifications include knowledge of safety distance

requirements and experience with the brake system

and its adjustment. When brake wear or other

factors extend press stopping time beyond the limit

permitted by the brake monitor, adjustment, repair,

or maintenance shall be performed on the brake or

other press system element that extends the

stopping time.

(iii) The brake monitor setting shall allow an

increase of no more than 10 percent of the longest

stopping time for the press, or 10 milliseconds,

whichever is longer, measured at the top of the

stroke.

(6)

Cycle control and control

systems.

(i) The

control system on presses used in the PSDI

mode shall meet the applicable requirements

of paragraphs (b)(7), (b)(8), (b)(13), and

(c)(5) of this section.

(ii) The control system shall incorporate a means

of dynamically monitoring for decoupling of the

rotary position indicating mechanism drive from the

crankshaft. This monitor shall stop slide motion

and prevent successive press strokes if decoupling

occurs, or if the monitor itself fails.

(iii) The mode selection means of paragraph

(b)(1)(iii) of this section shall have at least one

position for selection of the PSDI mode. Where more

than one interruption of the light sensing field is

used in the initiation of a stroke, either the mode

selection means must have one position for each

function, or a separate selection means shall be

provided which becomes operable when the PSDI mode

is selected. Selection of PSDI mode and the number

of interruptions/withdrawals of the light sensing

field required to initiate a press cycle shall be

by means capable of supervision by the

employer.

(iv) A PSDI set-up/reset means shall be provided

which requires an overt action by the operator, in

addition to PSDI mode selection, before operation

of the press by means of PSDI can be started.

(v) An indicator visible to the operator and

readily seen by the employer shall be provided

which shall clearly indicate that the system is

set-up for cycling in the PSDI mode.

(vi) The control system shall incorporate a timer

to deactivate PSDI when the press does not stroke

within the period of time set by the timer. The

timer shall be manually adjustable, to a maximum

time of 30 seconds. For any timer setting greater

than 15 seconds, the adjustment shall be made by

the use of a special tool available only to

authorized persons. Following a deactivation of

PSDI by the timer, the system shall make it

necessary to reset the set-up/reset means in order

to reactivate the PSDI mode.

(vii) Reactivation of PSDI operation following

deactivation of the PSDI mode from any other cause,

such as activation of the red color stop control

required by paragraph (b)(7)(ii) of this section,

interruption of the presence sensing field, opening

of an interlock, or reselection of the number of

sensing field interruptions/withdrawals required to

cycle the press, shall require resetting of the

set-up/reset means.

(viii) The control system shall incorporate an

automatic means to prevent initiation or continued

operation in the PSDI mode unless the press drive

motor is energized in the forward direction of

crankshaft rotation.

(ix) The control design shall preclude any movement

of the slide caused by operation of power on, power

off, or selector switches, or from checks for

proper operations as required by paragraph

(h)(6)(xiv) of this section.

(x) All components and subsystems of the control

system shall be designed to operate together to

provide total control system compliance with the

requirements of this section.

(xi) Where there is more than one operator of a

press used for PSDI, each operator shall be

protected by a separate, independently functioning,

presence sensing device. The control system shall

require that each sensing field be interrupted the

selected number of times prior to initiating a

stroke. Further, each operator shall be provided

with a set-up/reset means that meets the

requirements of paragraph (h)(6) of this section,

and which must be actuated to initiate operation of

the press in the PSDI mode.

(xii) [Reserved]

(xiii) The Control system shall incorporate

interlocks for supplemental guards, if used, which

will prevent stroke initiation or will stop a

stroke in progress if any supplemental guard fails

or is deactivated.

(xiv) The control system shall perform checks for

proper operation of all cycle control logic element

switches and contacts at least once each cycle.

Control elements shall be checked for correct

status after power “on” and before the initial PSDI

stroke.

(xv) The control system shall have provisions for

an “inch” operating means meeting the requirements

of paragraph (b)(7)(iv) of this section.

Die-setting shall not be done in the PSDI mode.

Production shall not be done in the “inch”

mode.

(xvi) The control system shall permit only a single

stroke per initiation command.

(xvii) Controls with internally stored programs

(e.g., mechanical, electro-mechanical, or

electronic) shall meet the requirements of

paragraph (b)(13) of this section, and shall

default to a predetermined safe condition in the

event of any single failure within the system.

Programmable controllers which meet the

requirements for controls with internally stored

programs stated above shall be permitted only if

all logic elements affecting the safety system and

point of operation safety are internally stored and

protected in such a manner that they cannot be

altered or manipulated by the user to an unsafe

condition.

(7)

Environmental

requirements.

Control components shall be selected, constructed, and

connected together in such a way as to withstand

expected operational and environmental stresses, at

least including those outlined in Appendix

A. Such stresses shall not so affect the control

system as to cause unsafe operation.

(8)

Safety

system.

(i)

Mechanical power presses used in the PSDI

mode shall be operated under the control of a

safety system which, in addition to meeting

the applicable requirements of paragraphs

(b)(13) and (c)(5) and other applicable

provisions of this section, shall function

such that a single failure or single

operating error shall not cause injury to

personnel from point of operation

hazards.

(ii) The safety system shall be designed,

constructed, and arranged as an integral total

system, including all elements of the press, the

controls, the safeguarding and any required

supplemental safeguarding, and their interfaces

with the operator and that part of the environment

which has effect on the protection against point of

operation hazards.

(9)

Safeguarding the point of

operation.

(i) The

point of operation of presses operated in the

PSDI mode shall be safeguarded in accordance

with the requirements of paragraph (c) of

this section, except that the safety distance

requirements of paragraph (h)(9)(v) of this

section shall be used for PSDI operation.

(ii)

(A)

PSDI shall be implemented only by use of

light curtain (photo- electric) presence

sensing devices which meet the

requirements of paragraph (c)(3)(iii)(c)

of this section unless the requirements

of the following paragraph have been

met.

(B) Alternatives to photo-electric light

curtains may be used for PSDI when the employer

can demonstrate, through tests and analysis by

the employer or the manufacturer, that the

alternative is as safe as the photo-electric

light curtain, that the alternative meets the

conditions of this section, has the same long

term reliability as light curtains and can be

integrated into the entire safety system as

provided for in this section. Prior to use,

both the employer and manufacturer must certify

that these requirements and all the other

applicable requirements of this section are met

and these certifications must be validated by

an OSHA-recognized third-party validation

organization to meet these additional

requirements and all the other applicable

requirements of paragraphs (a) through (h) and

Appendix A of this section. Three months prior

to the operation of any alternative system, the

employer must notify the OSHA Directorate of

Safety Standards programs of the name of the

system to be installed, the manufacturer and

the OSHA-recognized third-party validation

organization immediately. Upon request, the

employer must make available to that office all

tests and analyses for OSHA review.

(iii)

Individual sensing fields of presence sensing

devices used to initiate strokes in the PSDI

mode shall cover only one side of the

press.

(iv) Light curtains used for PSDI operation shall

have minimum object sensitivity not to exceed one

and one-fourth inches (31.75 mm). Where light

curtain object sensitivity is user-adjustable,

either discretely or continuously, design features

shall limit the minimum object sensitivity

adjustment not to exceed one and one-fourth inches

(31.75 mm). Blanking of the sensing field is not

permitted.

(v) The safety distance (Ds) from the sensing field

of the presence sensing device to the point of

operation shall be greater than or equal to the

distance determined by the formula:

Ds = Hs X (Ts + Tp + Tr + 2Tm) + Dp

Where:

Ds = Minimum safety distance.

Hs = Hand speed constant of 63 inches per second

(1.6 m/s).

Ts = Longest press stopping time, in seconds,

computed by taking averages of multiple

measurements at each of three positions (45

degrees, 60 degrees, and 90 degrees) of crankshaft

angular position; the longest of the three averages

is the stopping time to use. (Ts is defined as the

sum of the kinetic energy dissipation time plus the

pneumatic/magnetic/hydraulic reaction time of the

clutch/brake operating mechanism(s).)

Tp = Longest presence sensing device response time,

in seconds.

Tr = Longest response time, in seconds, of all

interposing control elements between the presence

sensing device and the clutch/brake operating

mechanism(s).

Tm = Increase in the press stopping time at the top

of the stroke, in seconds, allowed by the brake

monitor for brake wear. The time increase allowed

shall be limited to no more than 10 percent of the

longest press stopping time measured at the top of

the stroke, or 10 milliseconds, whichever is

longer.

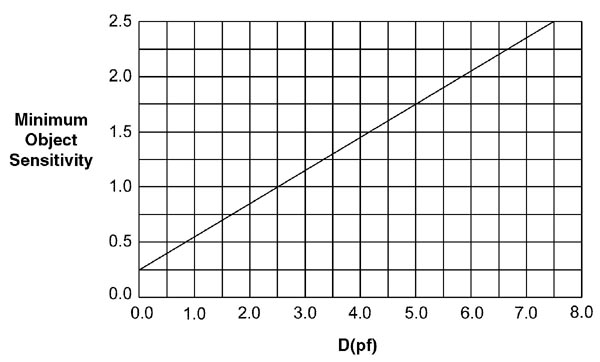

Dp = Penetration depth factor, required to provide

for possible penetration through the presence

sensing field by fingers or hand before detection

occurs. The penetration depth factor shall be

determined from Graph h-1 using the minimum object

sensitivity size.

Penetration

Depth Factor Calculation Graph

Dp = 3.4 (S-0.276)

(vi) The presence sensing device location shall

either be set at each tool change and set-up to

provide at least the minimum safety distance, or

fixed in location to provide a safety distance

greater than or equal to the minimum safety

distance for all tooling set-ups which are to be

used on that press.

(vii) Where presence sensing device location is

adjustable, adjustment shall require the use of a

special tool available only to authorized

persons.

(viii) Supplemental safeguarding shall be used to

protect all areas of access to the point of

operation which are unprotected by the PSDI

presence sensing device. Such supplemental

safeguarding shall consist of either additional

light curtain (photo-electric) presence sensing

devices or other types of guards which meet the

requirements of paragraphs (c) and (h) of this

section.

(A)

Presence sensing devices used as

supplemental safeguarding shall not

initiate a press stroke, and shall

conform to the requirements of paragraph

(c)(3)(iii) and other applicable

provisions of this section, except that

the safety distance shall comply with

paragraph (h)(9)(v) of this section.

(B) Guards used as supplemental safeguarding

shall conform to the design, construction and

application requirements of paragraph (c)(2) of

this section, and shall be interlocked with the

press control to prevent press PSDI operation

if the guard fails, is removed, or is out of

position.

(ix)

Barriers shall be fixed to the press frame or

bolster to prevent personnel from passing

completely through the sensing field, where

safety distance or press configuration is

such that personnel could pass through the

PSDI presence sensing field and assume a

position where the point of operation could

be accessed without detection by the PSDI

presence sensing device. As an alternative,

supplemental presence sensing devices used

only in the safeguard mode may be provided.

If used, these devices shall be located so as

to detect all operator locations and

positions not detected by the PSDI sensing

field, and shall prevent stroking or stop a

stroke in process when any supplemental

sensing field(s) are interrupted.

(x) Hand tools. Where tools are used for feeding,

removal of scrap, lubrication of parts, or removal

of parts that stick on the die in PSDI

operations:

(A)

The minimum diameter of the tool handle

extension shall be greater than the

minimum object sensitivity of the

presence sensing device(s) used to

initiate press strokes; or

(B) The length of the hand tool shall be such

as to ensure that the operator’s hand will be

detected for any safety distance required by

the press set-ups.

(10)Inspection

and maintenance.

(i) Any

press equipped with presence sensing devices

for use in PSDI, or for supplemental

safeguarding on presses used in the PSDI

mode, shall be equipped with a test rod of

diameter specified by the presence sensing

device manufacturer to represent the minimum

object sensitivity of the sensing field.

Instructions for use of the test rod shall be

noted on a label affixed to the presence

sensing device.

(ii) The following checks shall be made at the

beginning of each shift and whenever a die change

is made.

(A) A

check shall be performed using the test

rod according to the presence sensing

device manufacturer’s instructions to

determine that the presence sensing

device used for PSDI is operational.

(B) The safety distance shall be checked for

compliance with (h)(9)(v) of this section.

(C) A check shall be made to determine that all

supplemental safeguarding is in place. Where

presence sensing devices are used for

supplemental safeguarding, a check for proper

operation shall be performed using the test rod

according to the presence sensing device

manufacturer’s instructions.

(D) A check shall be made to assure that the

barriers and/or supplemental presence sensing

devices required by paragraph (h)(9)(ix) of

this section are operating properly.

(E) A system or visual check shall be made to

verify correct counterbalance adjustment for

die weight according to the press

manufacturer’s instructions, when a press is

equipped with a slide counterbalance

system.

(iii)

When presses used in the PSDI mode have

flywheel or bullgear running on crankshaft

mounted journals and bearings, or a flywheel

mounted on back shaft journals and bearings,

periodic inspections following the press

manufacturer’s recommendations shall be made

to ascertain that bearings are in good

working order, and that automatic lubrication

systems for these bearings (if automatic

lubrication is provided) are supplying proper

lubrication. On presses with provision for

manual lubrication of flywheel or bullgear

bearings, lubrication shall be provided

according to the press manufacturer’s

recommendations.

(iv) Periodic inspections of clutch and brake

mechanisms shall be performed to assure they are in

proper operating condition. The press

manufacturer’s recommendations shall be

followed.

(v) When any check of the press, including those

performed in accordance with the requirements of

paragraphs (h)(10)(ii), (iii) or (iv) of this

section, reveals a condition of noncompliance,

improper adjustment, or failure, the press shall

not be operated until the condition has been

corrected by adjustment, replacement, or

repair.

(vi) It shall be the responsibility of the employer

to ensure the competence of personnel caring for,

inspecting, and maintaining power presses equipped

for PSDI operation, through initial and periodic

training.

(11)

Safety system

certification/validation.

(i) Prior

to the initial use of any mechanical press in

the PSDI mode, two sets of certification and

validation are required:

(A)

The design of the safety system required

for the use of a press in the PSDI mode

shall be certified and validated prior to

installation. The manufacturer’s

certification shall be validated by an

OSHA-recognized third-party validation

organization to meet all applicable

requirements of paragraphs (a) through

(h) and Appendix A of this section.

(B) Alter a press has been equipped with a

safety system whose design has been certified

and validated in accordance with paragraph

(h)(11)(i) of this section, the safety system

installation shall be certified by the

employer, and then shall be validated by an

OSHA-recognized third-party validation

organization to meet all applicable

requirements of paragraphs (a) through (h) and

Appendix A of this section.

(ii) At

least annually thereafter, the safety system

on a mechanical power press used in the PSDI

mode shall be recertified by the employer and

revalidated by an OSHA-recognized third-party

validation organization to meet all

applicable requirements of paragraphs (a)

through (h) and Appendix A of this section.

Any press whose safety system has not been

recertified and revalidated within the

preceding 12 months shall be removed from

service in the PSDI mode until the safety

system is recertified and revalidated.

(iii) A label shall be affixed to the press as part

of each installation certification/validation and

the most recent recertification/revalidation. The

label shall indicate the press serial number, the

minimum safety distance (Ds) required by paragraph

(h)(9)(v) of this section, the fulfillment of

design certification/validation, the employer’s

signed certification, the identification of the

OSHA-recognized third-party validation

organization, its signed validation, and the date

the certification/validation and

recertification/revalidation are issued.

(iv) Records of the installation certification and

validation and the most recent recertification and

revalidation shall be maintained for each safety

system equipped press by the employer as long as

the press is in use. The records shall include the

manufacture and model number of each component and

subsystem, the calculations of the safety distance

as required by paragraph (h)(9)(v) of this section,

and the stopping time measurements required by

paragraph (h)(2)(ii) of this section. The most

recent records shall be made available to OSHA upon

request.

(v) The employer shall notify the OSHA-recognized

third-party validation organization within five

days whenever a component or a subsystem of the

safety system fails or modifications are made which

may affect the safety of the system. The failure of

a critical component shall necessitate the removal

of the safety system from service until it is

recertified and revalidated, except recertification

by the employer without revalidation is permitted

when a non-critical component or subsystem is

replaced by one of the same manufacture and design

as the original, or determined by the third-party

validation organization to be equivalent by

similarity analysis, as set forth in Appendix

A.

(vi) The employer shall notify the OSHA-recognized

third-party validation organization within five

days of the occurrence of any point of operation

injury while a press is used in the PSDI mode. This

is in addition to the report of injury required by

paragraph (g) of this section; however, a copy of

that report may be used for this

purpose.

(12)

Die setting and work

set-up.

(i) Die

setting on presses used in the PSDI mode

shall be performed in accordance with

paragraphs (d) and (h) of this section.

(ii) The PSDI mode shall not be used for die

setting or set-up. An alternative manual cycle

initiation and control means shall be supplied for

use in die setting which meets the requirements of

paragraph (b)(7) of this section.

(iii) Following a die change, the safety distance,

the proper application of supplemental

safeguarding, and the slide counterbalance

adjustment (if the press is equipped with a

counterbalance) shall be checked and maintained by

authorized persons whose qualifications include

knowledge of the safety distance, supplemental

safe-guarding requirements, and the manufacturer’s

specifications for counterbalance adjustment.

Adjustment of the location of the PSDI presence

sensing device shall require use of a special tool

available only to the authorized

persons.

(13)

Operator

training.

(i) The

operator training required by paragraph

(f)(2) of this section shall be provided to

the employee before the employee initially

operates the press and as needed to maintain

competence, but not less than annually

thereafter. It shall include instruction

relative to the following items for presses

used in the PSDI mode.

(A)

The manufacturer’s recommended test

procedures for checking operation of the

presence sensing device. This shall

include the use of the test rod required

by paragraph (h)(10)(i) of this

section.

(B) The safety distance required.

(C) The operation, function and performance of

the PSDI mode.

(D) The requirements for hand tools that may be

used in the PSDI mode.

(E) The severe consequences that can result if

he or she attempts to circumvent or by-pass any

of the safe-guard or operating functions of the

PSDI system.

(ii) The

employer shall certify that employees have

been trained by preparing a certification

record which includes the identity of the

person trained, the signature of the employer

or the person who conducted the training, and

the date the training was completed. The

certification record shall be prepared at the

completion of training and shall be

maintained on file for the duration of the

employee’s employment. The certification

record shall be made available upon request

to the Assistant Secretary for Occupational

Safety and Health.

[39 FR 32502,

June 27, 1974. as amended at 39 FR 41846, Dec. 23,

1974; 40 FR 3982, Jan. 27, 1975; 43 FR 49750, Oct.

24, 1978; 45 FR 8594, Feb. 8. 1980; 49 FR 18295, Apr.

30, 1984; 51 FR 34561, Sept. 29, 1986; 53 FR 8353,

Mar. 14, 1988; 54 FR 24333, June 7, 1989; 61 FR 5507,

Feb. 13, 1996; 61 FR 9227, March 7, 1996]

|